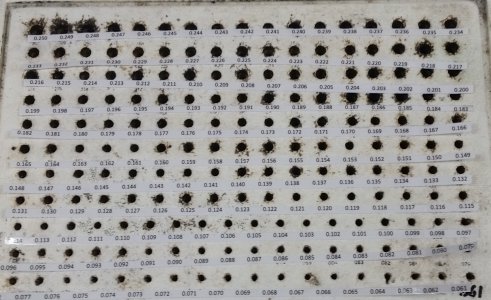

How about something like plastic corrugated boards.

https://www.michaels.com/plastic-corrugated-board-by-creatology/M10567770.html

Cheap, sturdy, easy to make holes in and maybe easy to mark?

https://www.michaels.com/plastic-corrugated-board-by-creatology/M10567770.html

Cheap, sturdy, easy to make holes in and maybe easy to mark?