- Joined

- Apr 27, 2014

- Messages

- 80

I got this heaped into a trade a few years ago, and it's been sitting on a shelf under my bench ever since. Got the gumption to pull it out and clean it up yesterday. It was coated in a thick, funky coat of greenish/bluish/greyish paint that appeared to have been applied with a roller by a four year old, had areas of surface rust, etc. it's not my intention to restore it, per se, merely clean it up so I can stand the look of it on my bench, and use it for small things.

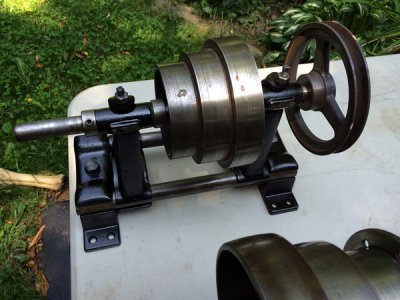

It came with a three jaw chuck, a small work rest, the cross slide, a bunch of collets, a jack shaft and an old GE motor. I'll need to come up with a belt for the pulleys, and I think I want to replace the felt wicks for the oilers.

Like a dolt, I failed to take any photos of it before I began cleanup, but I think you'll get a feel for it by seeing the photos.

Here's a shot of the pedestal feet, the one on the right is as it was, the one on the left after a combination of wire wheel and bead blasting:

The tail stock after cleanup:

Front of the bed after wire wheeling:

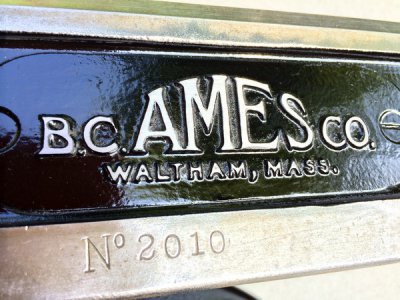

Sales plate on the right side of the bed:

More to follow!

- - - Updated - - -

Headstock stripped, masked and with a coat of paint:

Inner rail painted black - already starting to look like something!

Name plate in black. I intend to sand the tops of the lettering bare to add some contrast, this afternoon.

Black foot!

Tailstock after paint, polish and reassembly, sitting on the bed.

...to be continued.

It came with a three jaw chuck, a small work rest, the cross slide, a bunch of collets, a jack shaft and an old GE motor. I'll need to come up with a belt for the pulleys, and I think I want to replace the felt wicks for the oilers.

Like a dolt, I failed to take any photos of it before I began cleanup, but I think you'll get a feel for it by seeing the photos.

Here's a shot of the pedestal feet, the one on the right is as it was, the one on the left after a combination of wire wheel and bead blasting:

The tail stock after cleanup:

Front of the bed after wire wheeling:

Sales plate on the right side of the bed:

More to follow!

- - - Updated - - -

Headstock stripped, masked and with a coat of paint:

Inner rail painted black - already starting to look like something!

Name plate in black. I intend to sand the tops of the lettering bare to add some contrast, this afternoon.

Black foot!

Tailstock after paint, polish and reassembly, sitting on the bed.

...to be continued.