Hi All, a thread to share some info on my DRO setup & hopefully get some pointers on the finer details of the electronics & getting the most out of this system.

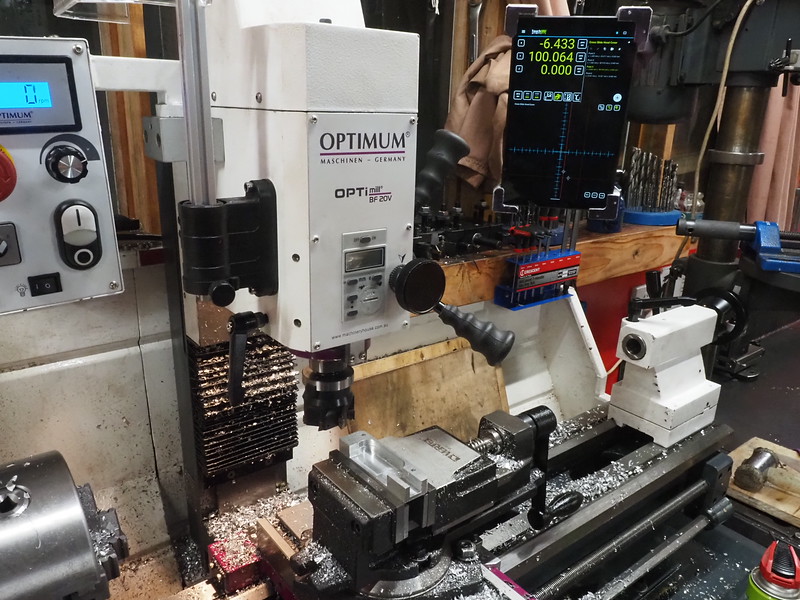

My machine is an Optimum Optiturn TU3008G lathe (12x28" benchtop machine) With an Optimill BF20V milling head bolted on the back. I bought all this new a couple of months ago. (a long awaited upgrade after many years with a worn old 10" Atlas)

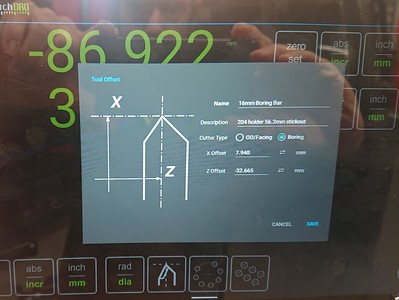

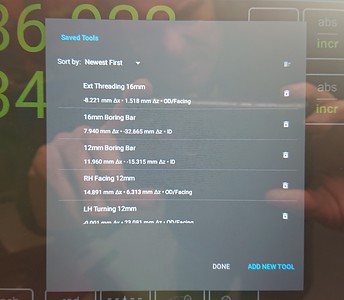

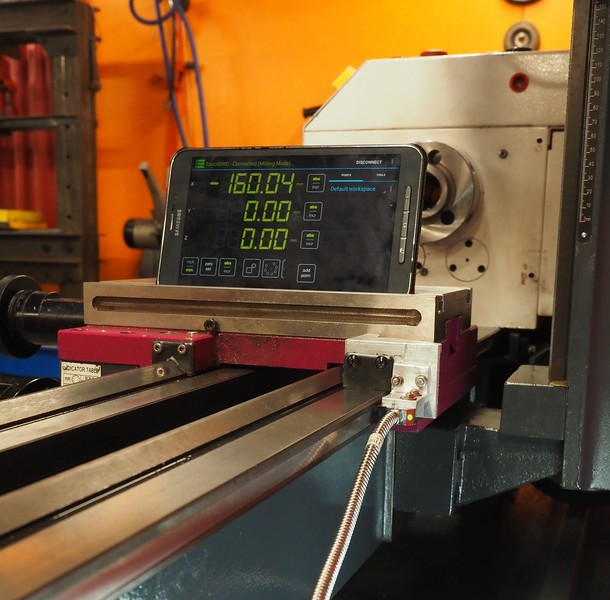

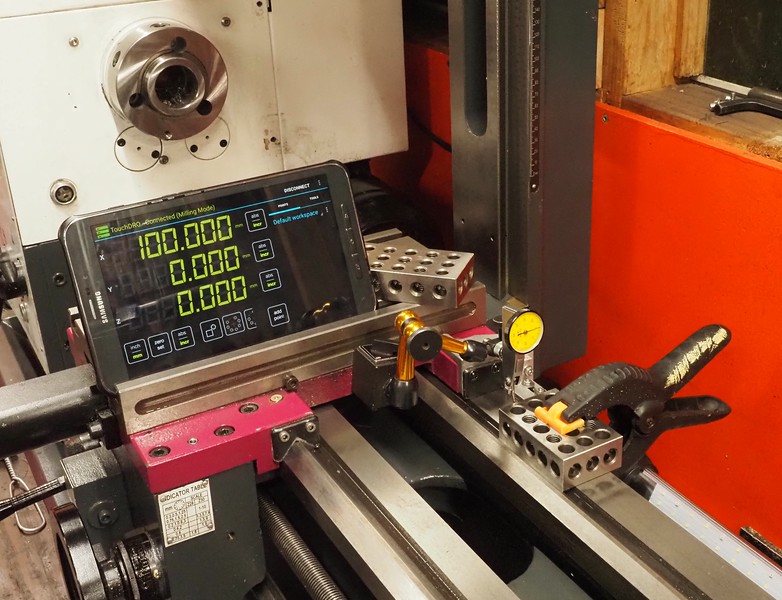

So I'm quite looking forward to the upcoming V3 of TouchDRO after reading about how it is better configurable for combo machines (if you need a beta tester @ycroosh please get in touch!) I got the deluxe 4 axis kit which made it's way slowly but surely to NZ.

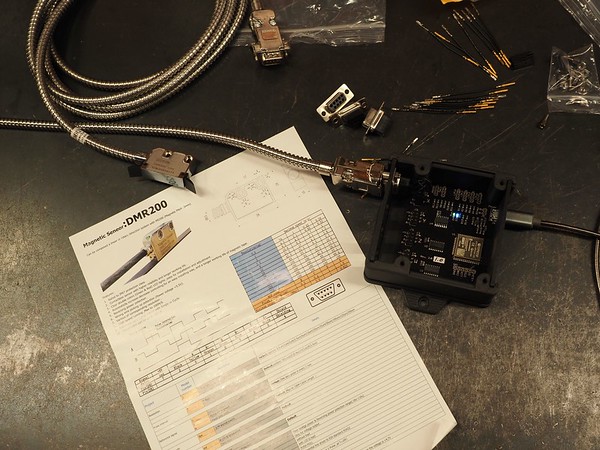

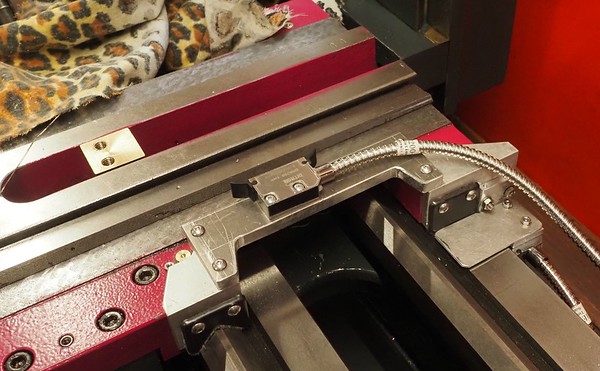

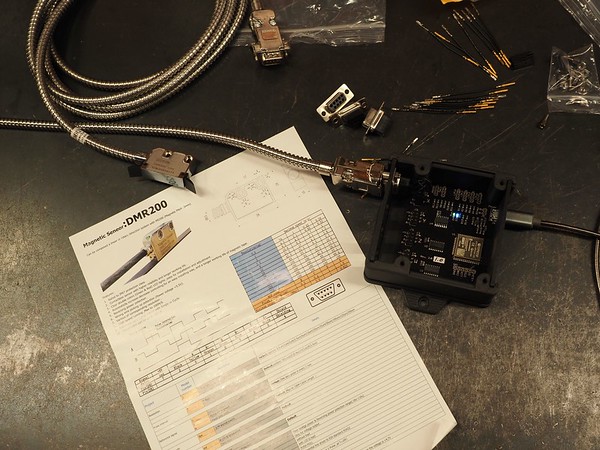

For scales I am using the magnetic type as both these machines come with slots pre-milled for stick-on magnetic strips. I ordered 3x Ditron DMR200 0.001mm from the 'Ditron Official Store' on Aliexpress, these were delivered in good time but they only sent 1m of '2+2' strip not the 2m ordered. After a few messages they are now hopefully sending me more strip. Fortunately the 1m is just enough to do the lathe axes for now.

The first problem was the discovery that the '10mm' groove in the back of the lathe bed was actually 9.85mm so the strip didn't fit. The cross slide slot which I did measure is 10mm+ but it looks like the mill column slot may be a little marginal too. So a bodgy shaper setup was devised to widen the lathe bed groove. Worked great, could do about 0.05mm per pass.

Next the magnetic strip was installed, it had a self adhesive strip on the back but that didn't want to hold in the groove despite a thorough clean, I had to use some spray adhesive which stuck it on well. The separate stainless steel cover strip stuck itself on fine.

Very carefully wired up the connectors. The Ditron wire colours in the plug matched their pin-out list & they seemed to power up fine. 5V, 0V, A, B, A', B' were all wired into the board leaving Z, Z' & Shield pins disconnected. Is it worth grounding the shield line? It's probably earthed at the read head?

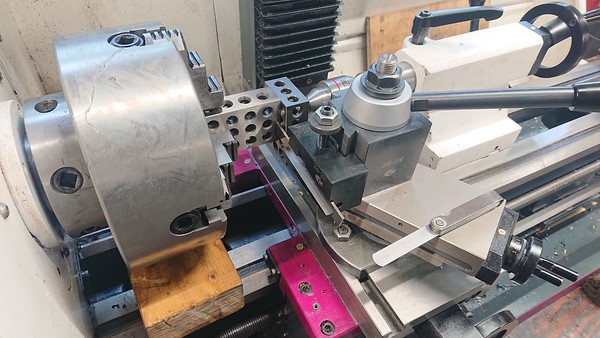

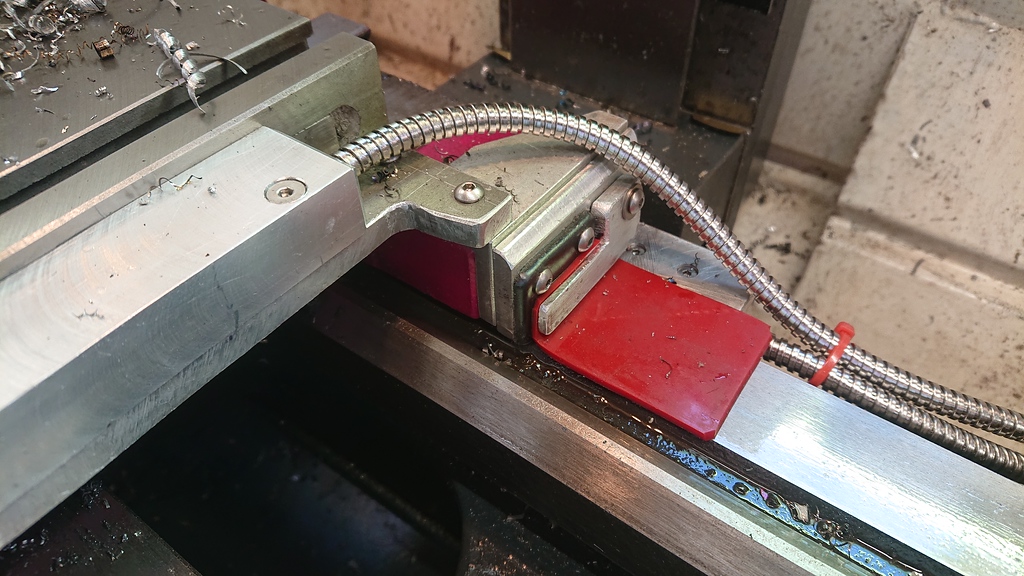

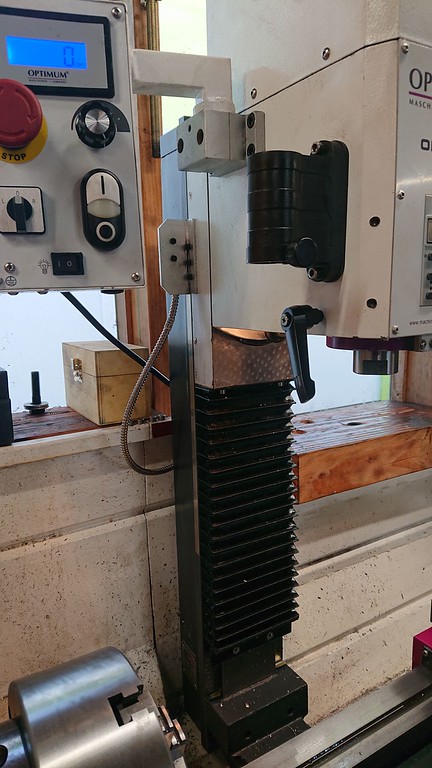

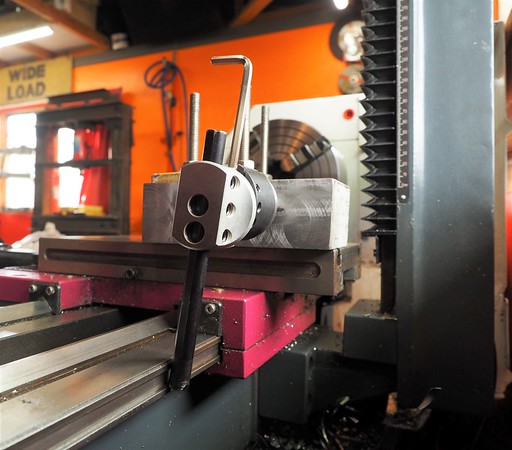

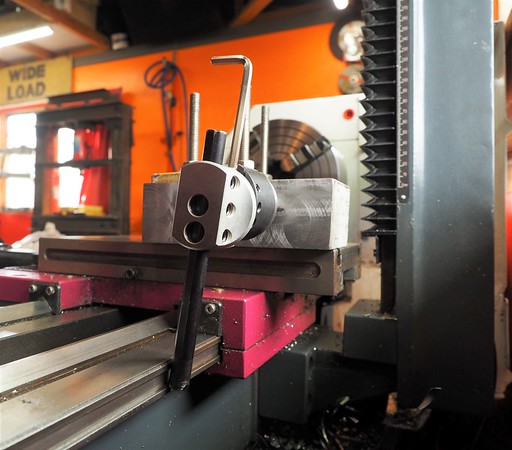

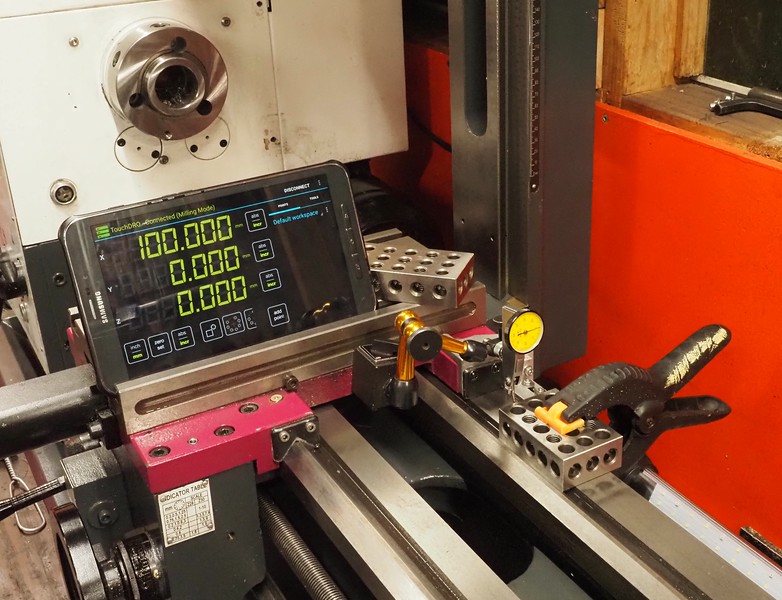

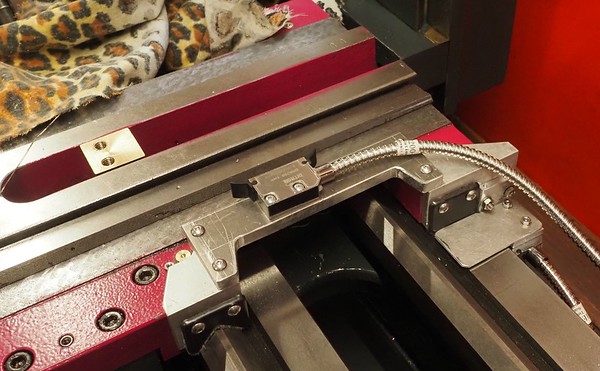

Then made some mounts, part of this will be re-made so there is a one piece wiper holder/ read head mount / protective cover. And it works!

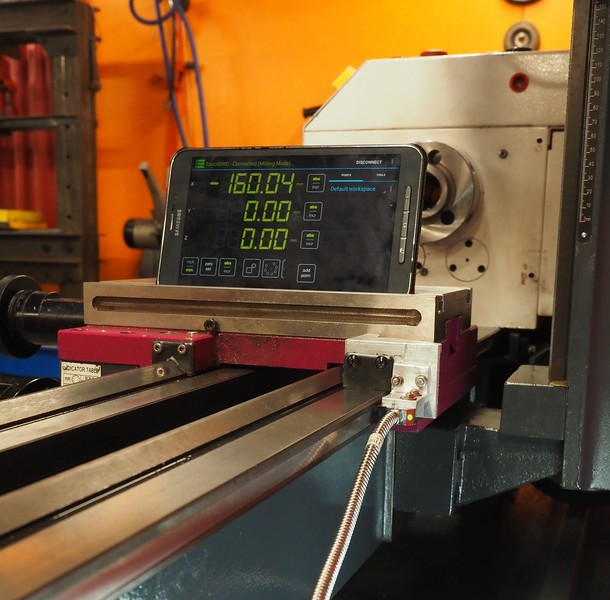

Calibration was fairly straightforward, had to tweak the cpi a bit after the first try but she's pretty close now. I got 25404.83 which I just realised will be 1 pulse per micron, 25400 is probably the correct number. Will re-check all this once all 3 axes are installed.

Cross slide next. Waiting on the cross slide to be ground to fix the shonky Z-axis level of the saddle vs lathe bed. Mount is mostly done though. 50x6mm alu angle was hacked up for the lower brackets then 8mm alu plate for the cross beam put the read head at just the right level. Will also mill out a burly cover for the read head. Unfortunately there was no way to get the read head outboard of where the tailstock comes in. May even dowel the mounting brackets so the top section can be lifted out if it's in the way then dropped back in right on line.

Cheers

Clint

My machine is an Optimum Optiturn TU3008G lathe (12x28" benchtop machine) With an Optimill BF20V milling head bolted on the back. I bought all this new a couple of months ago. (a long awaited upgrade after many years with a worn old 10" Atlas)

So I'm quite looking forward to the upcoming V3 of TouchDRO after reading about how it is better configurable for combo machines (if you need a beta tester @ycroosh please get in touch!) I got the deluxe 4 axis kit which made it's way slowly but surely to NZ.

For scales I am using the magnetic type as both these machines come with slots pre-milled for stick-on magnetic strips. I ordered 3x Ditron DMR200 0.001mm from the 'Ditron Official Store' on Aliexpress, these were delivered in good time but they only sent 1m of '2+2' strip not the 2m ordered. After a few messages they are now hopefully sending me more strip. Fortunately the 1m is just enough to do the lathe axes for now.

The first problem was the discovery that the '10mm' groove in the back of the lathe bed was actually 9.85mm so the strip didn't fit. The cross slide slot which I did measure is 10mm+ but it looks like the mill column slot may be a little marginal too. So a bodgy shaper setup was devised to widen the lathe bed groove. Worked great, could do about 0.05mm per pass.

Next the magnetic strip was installed, it had a self adhesive strip on the back but that didn't want to hold in the groove despite a thorough clean, I had to use some spray adhesive which stuck it on well. The separate stainless steel cover strip stuck itself on fine.

Very carefully wired up the connectors. The Ditron wire colours in the plug matched their pin-out list & they seemed to power up fine. 5V, 0V, A, B, A', B' were all wired into the board leaving Z, Z' & Shield pins disconnected. Is it worth grounding the shield line? It's probably earthed at the read head?

Then made some mounts, part of this will be re-made so there is a one piece wiper holder/ read head mount / protective cover. And it works!

Calibration was fairly straightforward, had to tweak the cpi a bit after the first try but she's pretty close now. I got 25404.83 which I just realised will be 1 pulse per micron, 25400 is probably the correct number. Will re-check all this once all 3 axes are installed.

Cross slide next. Waiting on the cross slide to be ground to fix the shonky Z-axis level of the saddle vs lathe bed. Mount is mostly done though. 50x6mm alu angle was hacked up for the lower brackets then 8mm alu plate for the cross beam put the read head at just the right level. Will also mill out a burly cover for the read head. Unfortunately there was no way to get the read head outboard of where the tailstock comes in. May even dowel the mounting brackets so the top section can be lifted out if it's in the way then dropped back in right on line.

Cheers

Clint

Last edited: