I'm a firearms manufacturer but I've only dealt with 3d prints and parts kits. Trying to get a mill to first cut some lead molds and eventually hardened steel.

I've got a bead on a couple different secondhand machines around my area

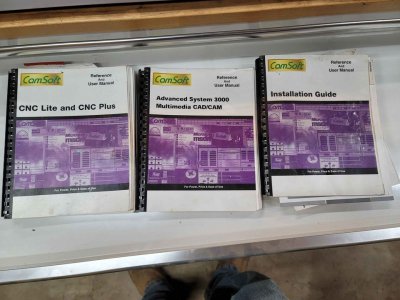

1. Milltronics Partner IV CNC running camsoft, little info on the controller. Specifically mentioned DXF files which

Vertical knee mill

Looks a bit rough and in don't see a coolant system on it.

I don't know anything about this brand.

The guys a machinist so I imagine he'll remember more if he wants to sell it $6000.

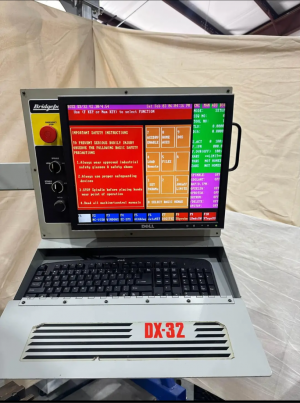

2. Bridgeport v2xt

Vertical knee mill dated maybe around 2010

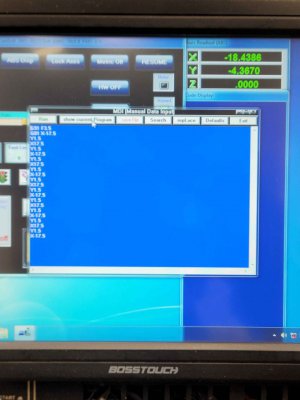

Im not sure what software its running specifically seems like the program reads BOSS dx32 2.38/4.54. I am not sure why there are 2 versions that or that's not a version number but some sort of metric. I got that its probably boss but I want to get a date on the software version.

Looks in great shape, everyone knows bridgeport. Aftermarket is active but if I buy it and then immediately have to retrofit the controller im gonna kick my neighbors truck where he usually kicks it after yelling at his wife.

$9000

Tormach

There's a couple tormachs around me but the dudes want ridiculous prices and I'd be better off buying new at that point except I'd have to get an 1100 and I m not thrilled about paying $25k to cut hard steel but if course there's a progression I could do instead of outright getting a usable machine.

Something I hadn't thought about was auto tool changing. Id imagine the bridgeport and milltronics wouldn't support that. I'm also eying to familiarize myself with these older software's as Im spoiled by 3d printing gcode slices.

I also saw some stuff about the speed of the knee mill cnc's being kind of slow which I imagine something like a tormach will always be faster because its not slinging a large 48" 200lb bed

I've got a bead on a couple different secondhand machines around my area

1. Milltronics Partner IV CNC running camsoft, little info on the controller. Specifically mentioned DXF files which

Vertical knee mill

Looks a bit rough and in don't see a coolant system on it.

I don't know anything about this brand.

The guys a machinist so I imagine he'll remember more if he wants to sell it $6000.

2. Bridgeport v2xt

Vertical knee mill dated maybe around 2010

Im not sure what software its running specifically seems like the program reads BOSS dx32 2.38/4.54. I am not sure why there are 2 versions that or that's not a version number but some sort of metric. I got that its probably boss but I want to get a date on the software version.

Looks in great shape, everyone knows bridgeport. Aftermarket is active but if I buy it and then immediately have to retrofit the controller im gonna kick my neighbors truck where he usually kicks it after yelling at his wife.

$9000

Tormach

There's a couple tormachs around me but the dudes want ridiculous prices and I'd be better off buying new at that point except I'd have to get an 1100 and I m not thrilled about paying $25k to cut hard steel but if course there's a progression I could do instead of outright getting a usable machine.

Something I hadn't thought about was auto tool changing. Id imagine the bridgeport and milltronics wouldn't support that. I'm also eying to familiarize myself with these older software's as Im spoiled by 3d printing gcode slices.

I also saw some stuff about the speed of the knee mill cnc's being kind of slow which I imagine something like a tormach will always be faster because its not slinging a large 48" 200lb bed