Began assembly of our CNC plasma table today. Looked at the usual suspects (Lincoln Torchmate, ShopSaber, STV). Lots of options and all pretty expensive for what you get I think. We're months away from making money given the learning curve so I didn't want to break the bank by financing and paying interest. But I do want to make money and work envelope was a consideration. Langmuir Systems has a new model (the XR). A 4x8 table with driven ball-nut on ball screws (no whipping at higher speeds). Really good cost for performance from what we can tell. Parts quality seems excellent overall.

Frame is 12 gauge C-channel and nicely made. Where heavy brackets are attached, Langmuire includes equally heavy reinforcing brackets on the back side. Engineered to a price point but smart about it. Looks pretty rugged for a prosumer-grade tool.

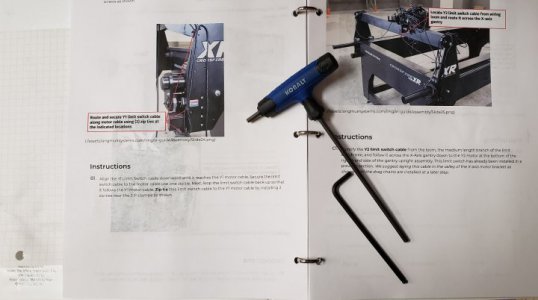

Parts packaging and organization is excellent. The assembly manual is the best I've ever seen...120 pages, color pictures and very very thorough.

By contrast, professional grade stuff is welded and shipped as a finished or nearly finished assembly (and ruinously expensive to get it to your loading dock).

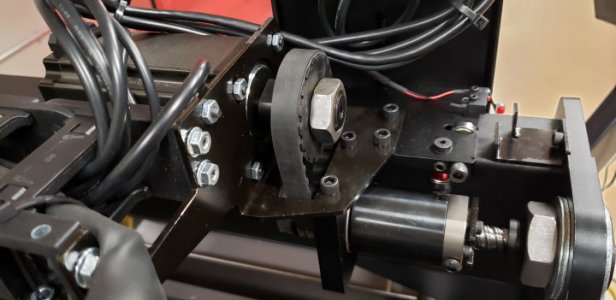

Assembling the gantry. 1/2" aluminum construction. For about 1/3 the price of a Torchmate 4xxx series, this seems a lot more than 1/3 as good.

More to come.

Frame is 12 gauge C-channel and nicely made. Where heavy brackets are attached, Langmuire includes equally heavy reinforcing brackets on the back side. Engineered to a price point but smart about it. Looks pretty rugged for a prosumer-grade tool.

Parts packaging and organization is excellent. The assembly manual is the best I've ever seen...120 pages, color pictures and very very thorough.

By contrast, professional grade stuff is welded and shipped as a finished or nearly finished assembly (and ruinously expensive to get it to your loading dock).

Assembling the gantry. 1/2" aluminum construction. For about 1/3 the price of a Torchmate 4xxx series, this seems a lot more than 1/3 as good.

More to come.

Last edited: