Hey guys. I'm so glad that I found out for this community!

Few years back, I have worked with some CNC mill and lathe, so I am familiar with writing G code and stuff.

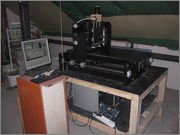

I had an idea to make cnc for myself, and I choose JGRO design for it with some changes.

First, I have made 3D assembly in Catia, with all necessary parts.

Material is MDF. Lead screw is 16mm diameter with anti backlash nut.

I am using step motors Nema23. I have bought electronics on ebay.

I bought these linear berings, four big 20mm diameter, and eight of them smaller, 16mm diameter.

Adjustment blocks:

Two of axis are ballscrews and one (Z axis) is regular leadscrew. I Think at some time I will replace it also with ballscrew.

This picture is old, and on the table is just one big (x axis) ballscrew. Right beside it is some leadscrew from old car jackscrew. I didn't use it.

And of course MDF:

Few years back, I have worked with some CNC mill and lathe, so I am familiar with writing G code and stuff.

I had an idea to make cnc for myself, and I choose JGRO design for it with some changes.

First, I have made 3D assembly in Catia, with all necessary parts.

Material is MDF. Lead screw is 16mm diameter with anti backlash nut.

I am using step motors Nema23. I have bought electronics on ebay.

I bought these linear berings, four big 20mm diameter, and eight of them smaller, 16mm diameter.

Adjustment blocks:

Two of axis are ballscrews and one (Z axis) is regular leadscrew. I Think at some time I will replace it also with ballscrew.

This picture is old, and on the table is just one big (x axis) ballscrew. Right beside it is some leadscrew from old car jackscrew. I didn't use it.

And of course MDF:

Last edited by a moderator: