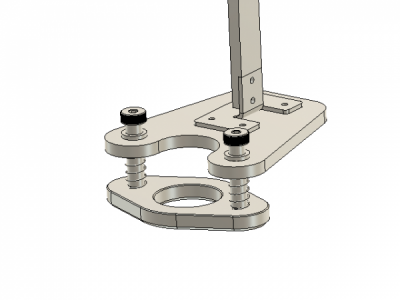

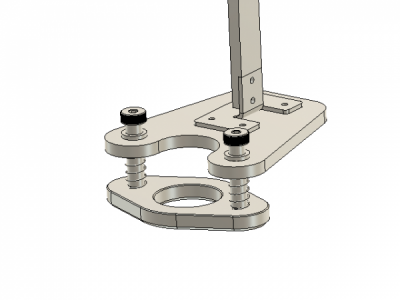

I've been thinking about building a pressure foot for ages. Never could find the time and I wasn't about to buy one. So just before Christmas I picked up some hardware set out to design on based on the commercial version found here: https://store.shopbottools.com/products/cnc-pressure-foot

Today I decided to give it a try on some parts I needed to cut out. Worked absolutely fantastic. This router has never cut so quite! Especially in the +X direction where it would often wine a bit.

I wanted the foot to look factory... I may have over done it this time.

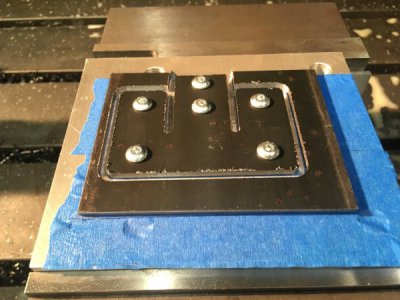

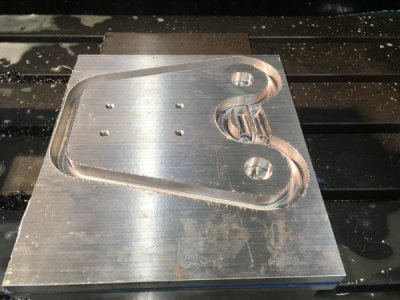

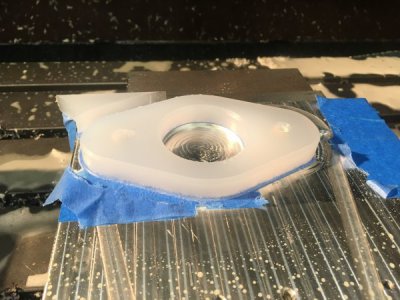

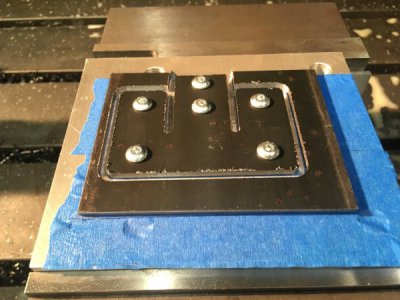

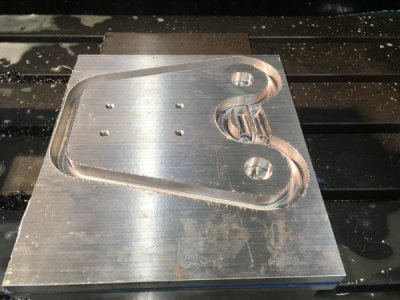

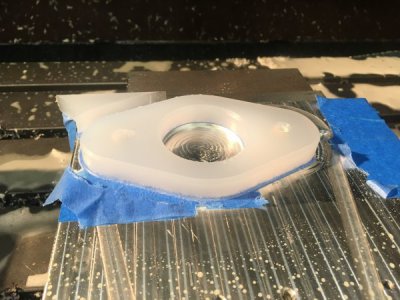

Most of the parts were made on the cnc mill as opposed to the router. I fixtured most of the parts using painters tape and super glue. The advantage of the mill is being able to rigid tap screw holes when needed. I don't totally trust the blue tape but in this case I had to really pry to get the aluminum foot free so my confidence is growing even with flood coolant. The main aluminum foot was tumbled and then anodized. I still need to take it apart and paint the steel bracket. For the test parts on the router today I held the sheet down with three pieces of blue tape, with the foot it was more than enough. Enjoy!

Today I decided to give it a try on some parts I needed to cut out. Worked absolutely fantastic. This router has never cut so quite! Especially in the +X direction where it would often wine a bit.

I wanted the foot to look factory... I may have over done it this time.

Most of the parts were made on the cnc mill as opposed to the router. I fixtured most of the parts using painters tape and super glue. The advantage of the mill is being able to rigid tap screw holes when needed. I don't totally trust the blue tape but in this case I had to really pry to get the aluminum foot free so my confidence is growing even with flood coolant. The main aluminum foot was tumbled and then anodized. I still need to take it apart and paint the steel bracket. For the test parts on the router today I held the sheet down with three pieces of blue tape, with the foot it was more than enough. Enjoy!