- Joined

- Mar 26, 2018

- Messages

- 8,407

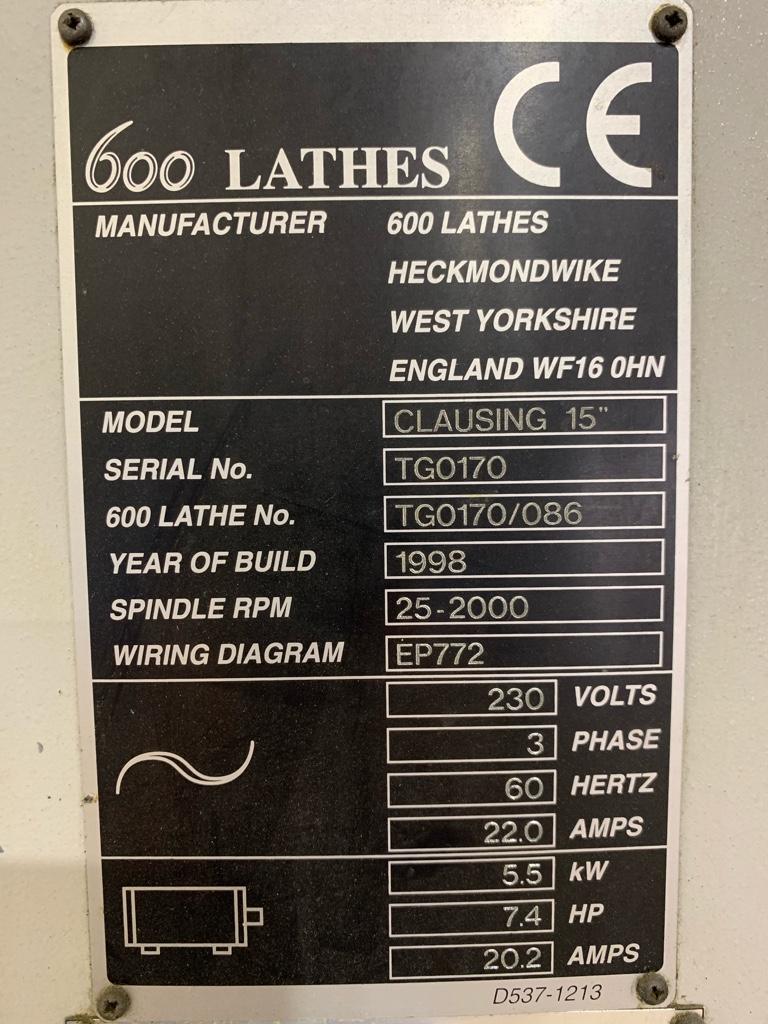

Well, its a square head gap-bed, apron handwheel on the left. 1996 I think, need to look at the badge again.

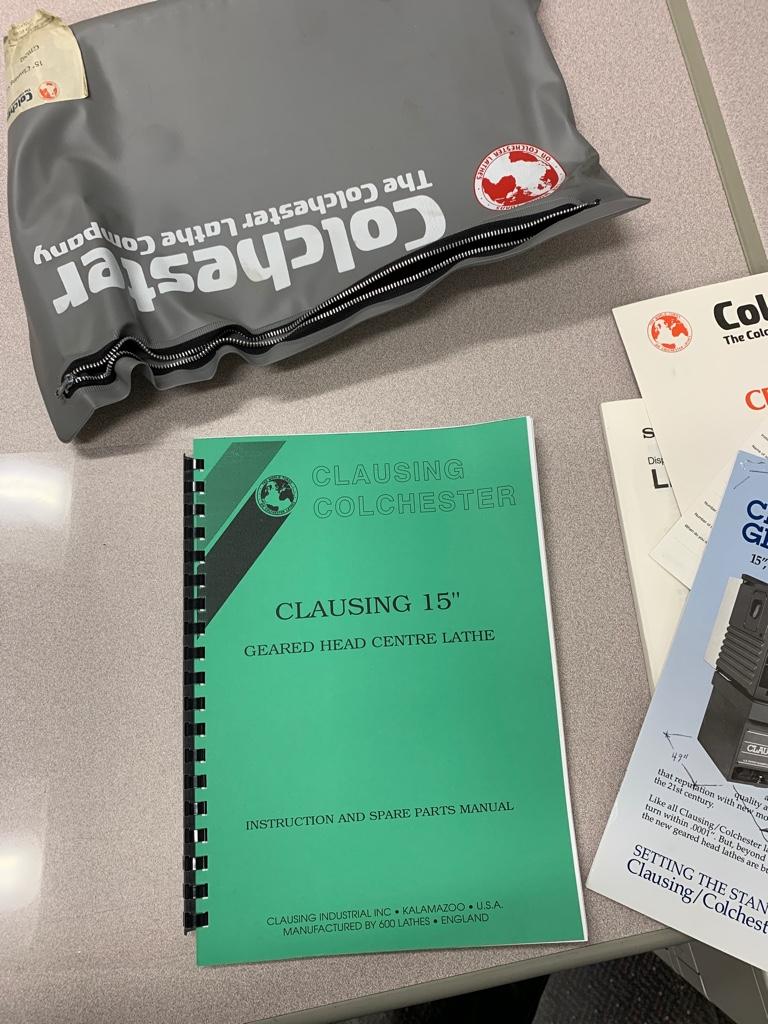

Have never been able to find the ‘exact’ owner’s manual, but have a couple that are close.

Sent from my iPhone using Tapatalk

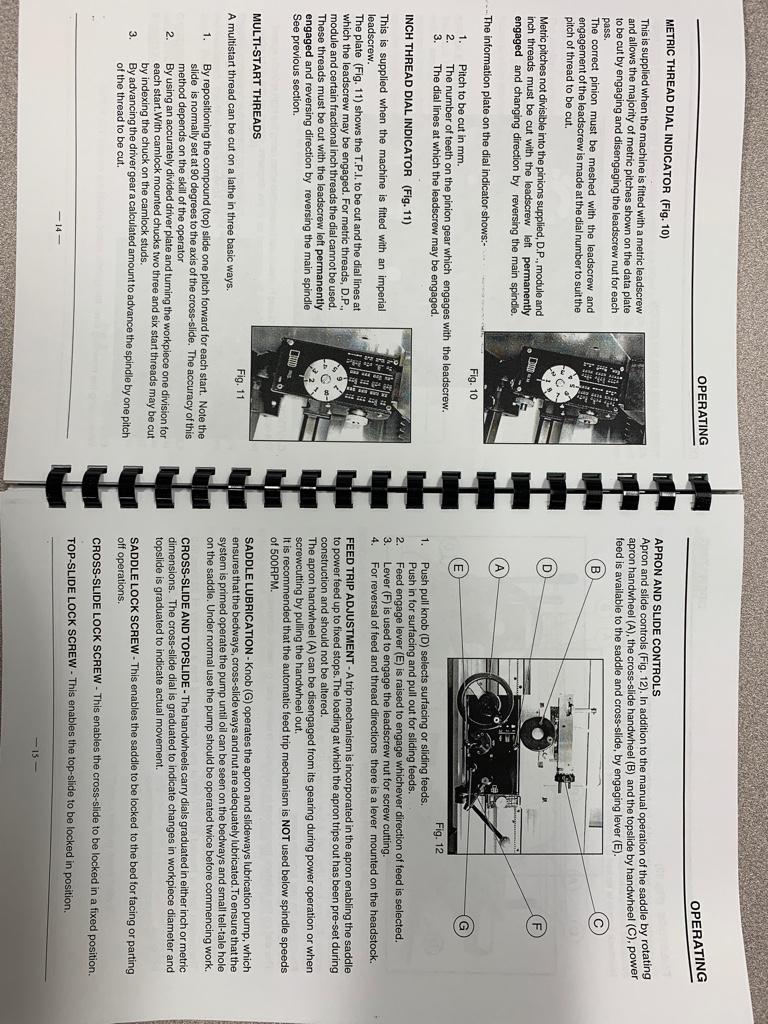

I don't see the tension adjustment knob on the left side of the apron.

You can contact Clausing customer service, give them your serial number and download a PDF of the manual, I think.

No chip pan?