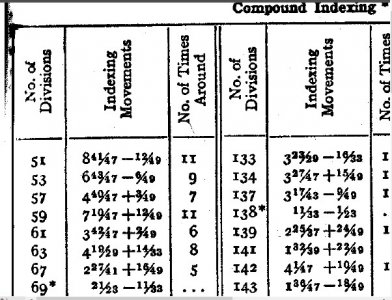

I did some more research on this and found that the older index heads came with the stop pin feature for compound indexing, but it has largely faded away since the advent of NC and CNC and the ability to layout a hole circle on a mill without an indexer. So, those of you that have some of the older index heads may have this ability. The newer ones do not, but I found a couple of YouTube videos showing what one fellow did to be able to do compound indexing with a modern indexing head.

[video=youtube;exruE7sHXso]https://www.youtube.com/watch?v=exruE7sHXso[/video]

[video=youtube;S1zovk1KODs]https://www.youtube.com/watch?v=S1zovk1KODs[/video]

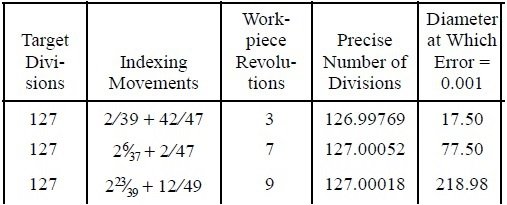

I also did some digging and found the necessary numbers for 127 divisions in Machinery's Handbook:

View attachment 92952

Keep in mind that this chart assumes a 40:1 ratio as you would find with an indexing head, and they will not work with a rotary table, which usually uses a 90:1 ratio. Sadly, a chart does not exist for a 90:1 ratio, nor did they supply the math to figure it out, and I have not yet gotten through it myself with any real success, so I suspect I am missing something.

Hope you all find this useful!