- Joined

- Feb 24, 2019

- Messages

- 925

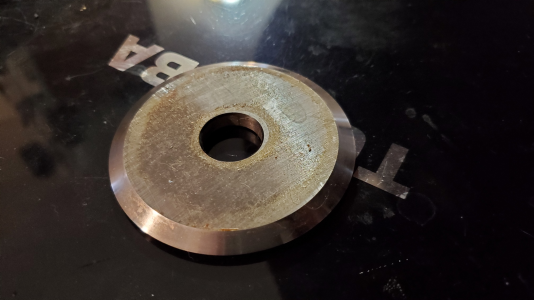

Each wheel will be independent, and the holder of the wheel will need to be positional and adjustable. Some setups they could be a half inch apart, others (in the current planning stage) 22 inches apart. I have plans for up to 10 of these units. I figured half would be lefties, half would be righties.Do the wheels need to be independent of each other? Headless shoulder screws are available, also low profile heads are available, would likely take up less space than the clip.

McMaster-Carr

McMaster-Carr is the complete source for your plant with over 595,000 products. 98% of products ordered ship from stock and deliver same or next day.www.mcmaster.com