- Joined

- Jan 6, 2017

- Messages

- 1,214

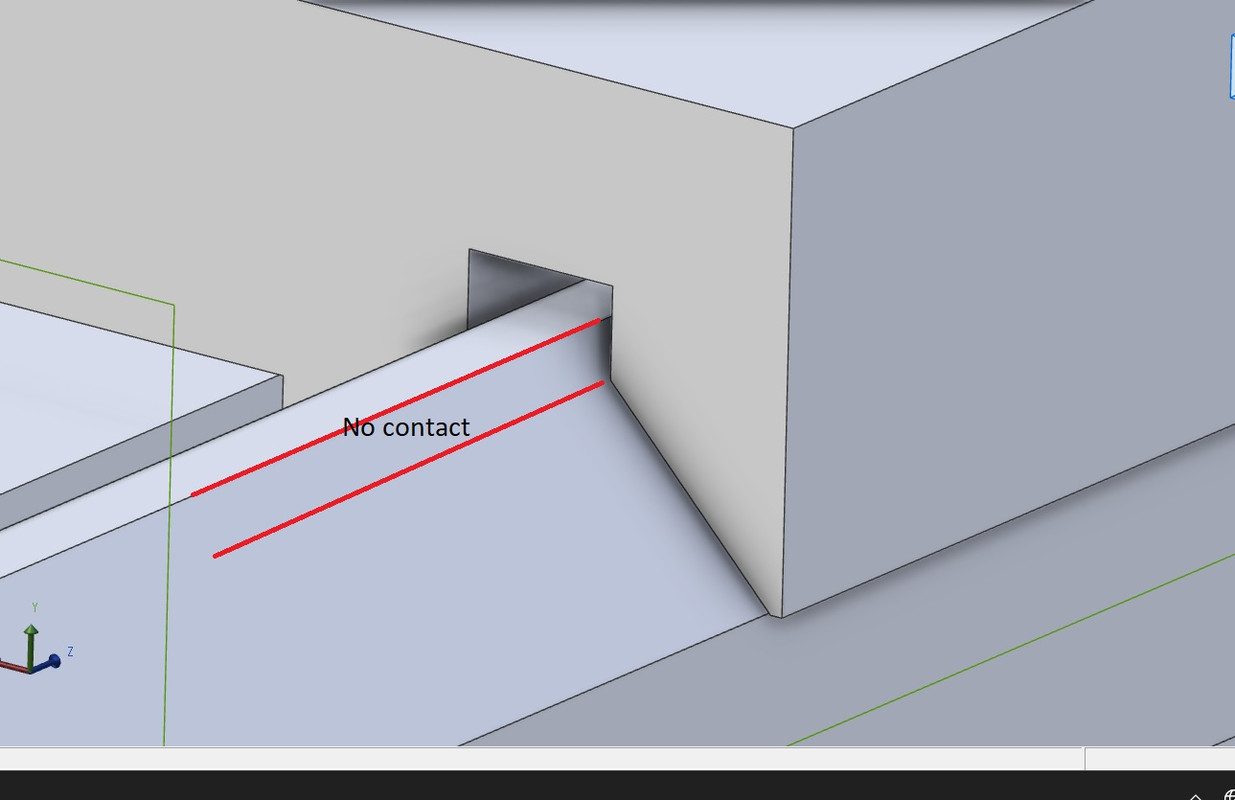

The bed on my lathe has minimal wear, and I recently scraped the underside of the saddle to improve the amout of contact area. While I had it apart, I noticed that the V under the saddle doesn't fully contact the beds V way. There is an about 3/16" wide where the saddle doesn't contact the ways because the milled notch in the top of the V is too wide.

Like this:

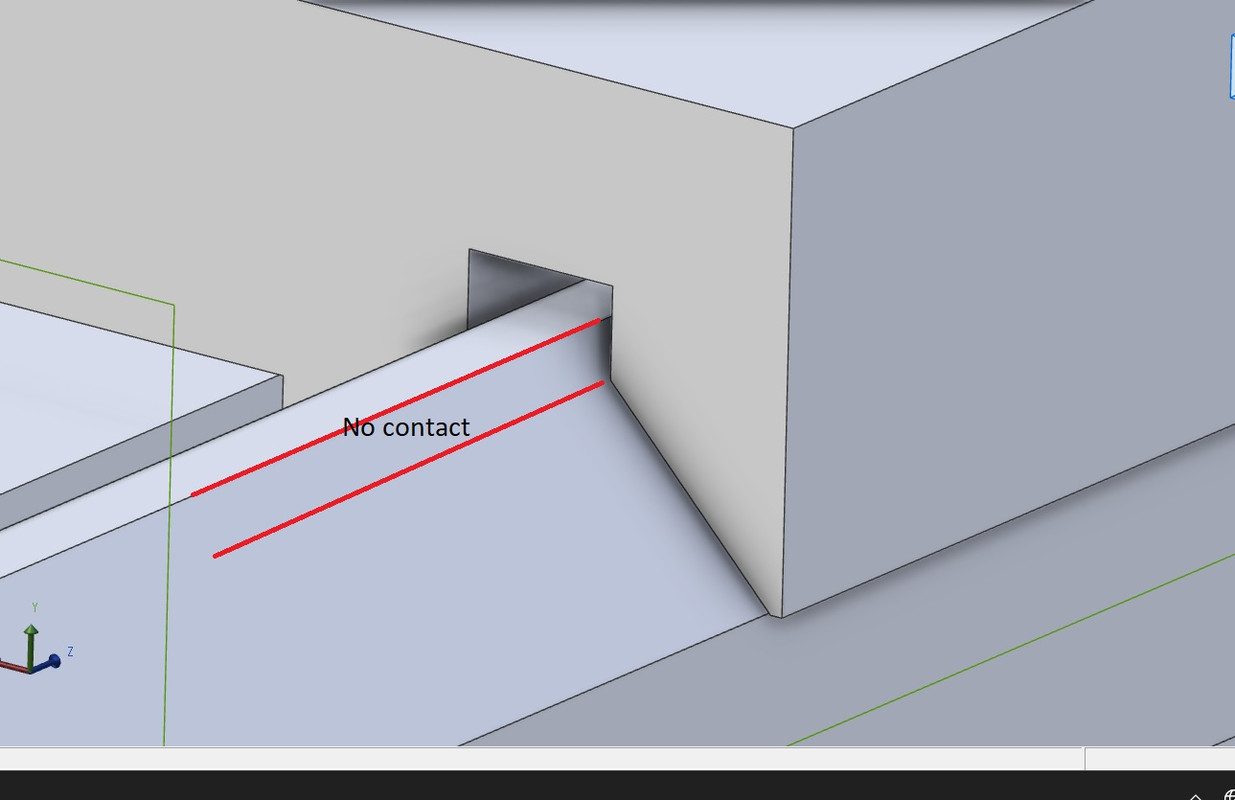

I was considering milling the surfaces, adding some Turcite and scraping it in, to correct this. I was thinking about using the Turcite epoxy/cement to partially infill the milled notch, in order to get full contact across the ways.

Something like this:

Then afterward, scraping in the Turcite.

Is there any reason this wouldn't work? Should I leave it alone, or is this worth addressing with Turcite?

Like this:

I was considering milling the surfaces, adding some Turcite and scraping it in, to correct this. I was thinking about using the Turcite epoxy/cement to partially infill the milled notch, in order to get full contact across the ways.

Something like this:

Then afterward, scraping in the Turcite.

Is there any reason this wouldn't work? Should I leave it alone, or is this worth addressing with Turcite?

Last edited: