- Joined

- Apr 29, 2019

- Messages

- 2,061

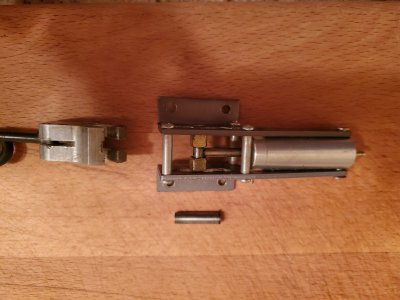

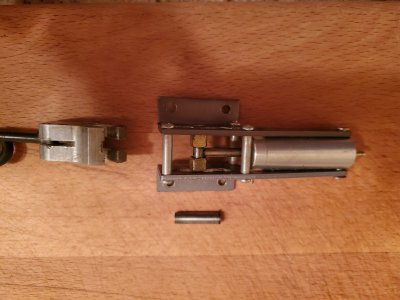

For those that do not know what a retractable landing gear looks like, This is what I am starting from. It is an old Robart 500 series main gear.

My goal is to replace the pneumatic cylinder with an electric motor/actuator. It is the aluminum cylinder and its shaft that I will need to replace with new parts. I will be making a new aluminum cylinder to the same outside dimensions but with the gear motor shown above inside of it. The threaded output shaft will need to be cut to length, I I will have to figure out a "nut" to ride on the thread and interface with the gear trunion while riding in that wavy slot in the side of the gear.

And yes I did manage to loose the Jesus clip that held that pin in place as it left the area at mach 2 as I was removing it. I even held my cupped hand over it and was working on a white towel so that it would not vanish. Of course it is made of beryllium copper and I never got around to buying a Beryllium copper magnet to aid in the search. It is really tiny Ø7/32 shaft and only a 0.012 cross section. New ones are in my McMaster cart waiting for more parts needed, otherwise the postage would be more than the parts. I know I will be needing some tooling and material for this job.

OK Back to the drawing board.......

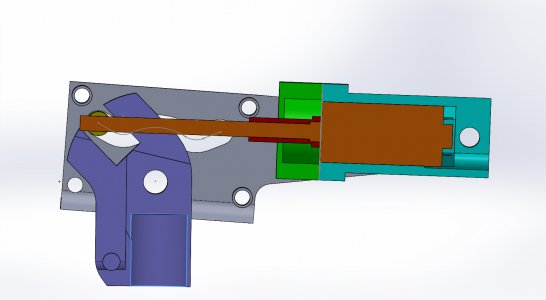

This is the gear up position

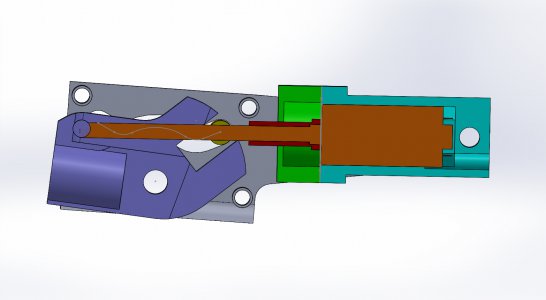

This is the gear down position

Disassembled top view.

Disassembled side view.

My goal is to replace the pneumatic cylinder with an electric motor/actuator. It is the aluminum cylinder and its shaft that I will need to replace with new parts. I will be making a new aluminum cylinder to the same outside dimensions but with the gear motor shown above inside of it. The threaded output shaft will need to be cut to length, I I will have to figure out a "nut" to ride on the thread and interface with the gear trunion while riding in that wavy slot in the side of the gear.

And yes I did manage to loose the Jesus clip that held that pin in place as it left the area at mach 2 as I was removing it. I even held my cupped hand over it and was working on a white towel so that it would not vanish. Of course it is made of beryllium copper and I never got around to buying a Beryllium copper magnet to aid in the search. It is really tiny Ø7/32 shaft and only a 0.012 cross section. New ones are in my McMaster cart waiting for more parts needed, otherwise the postage would be more than the parts. I know I will be needing some tooling and material for this job.

OK Back to the drawing board.......

This is the gear up position

This is the gear down position

Disassembled top view.

Disassembled side view.