- Joined

- Jan 20, 2021

- Messages

- 296

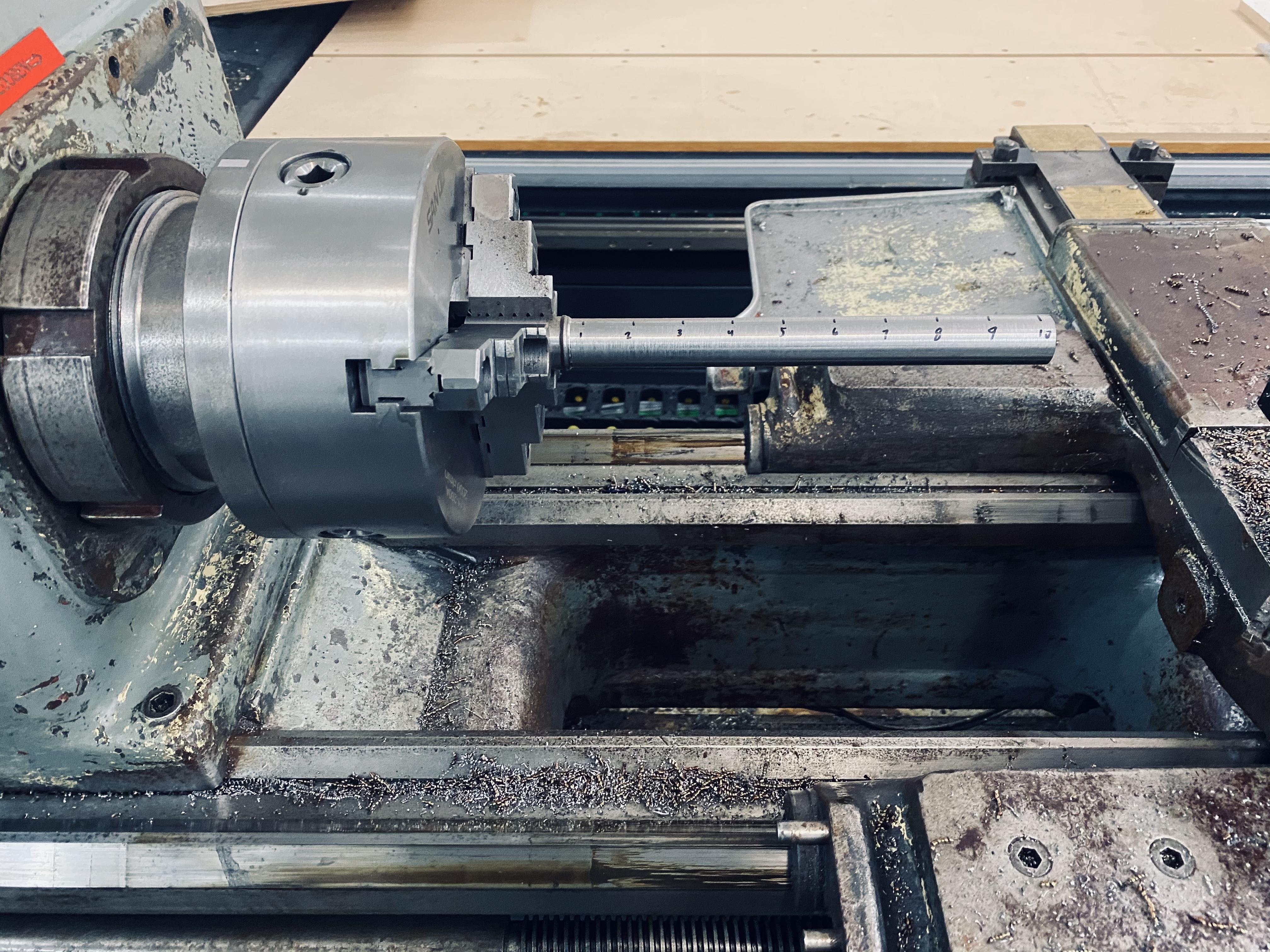

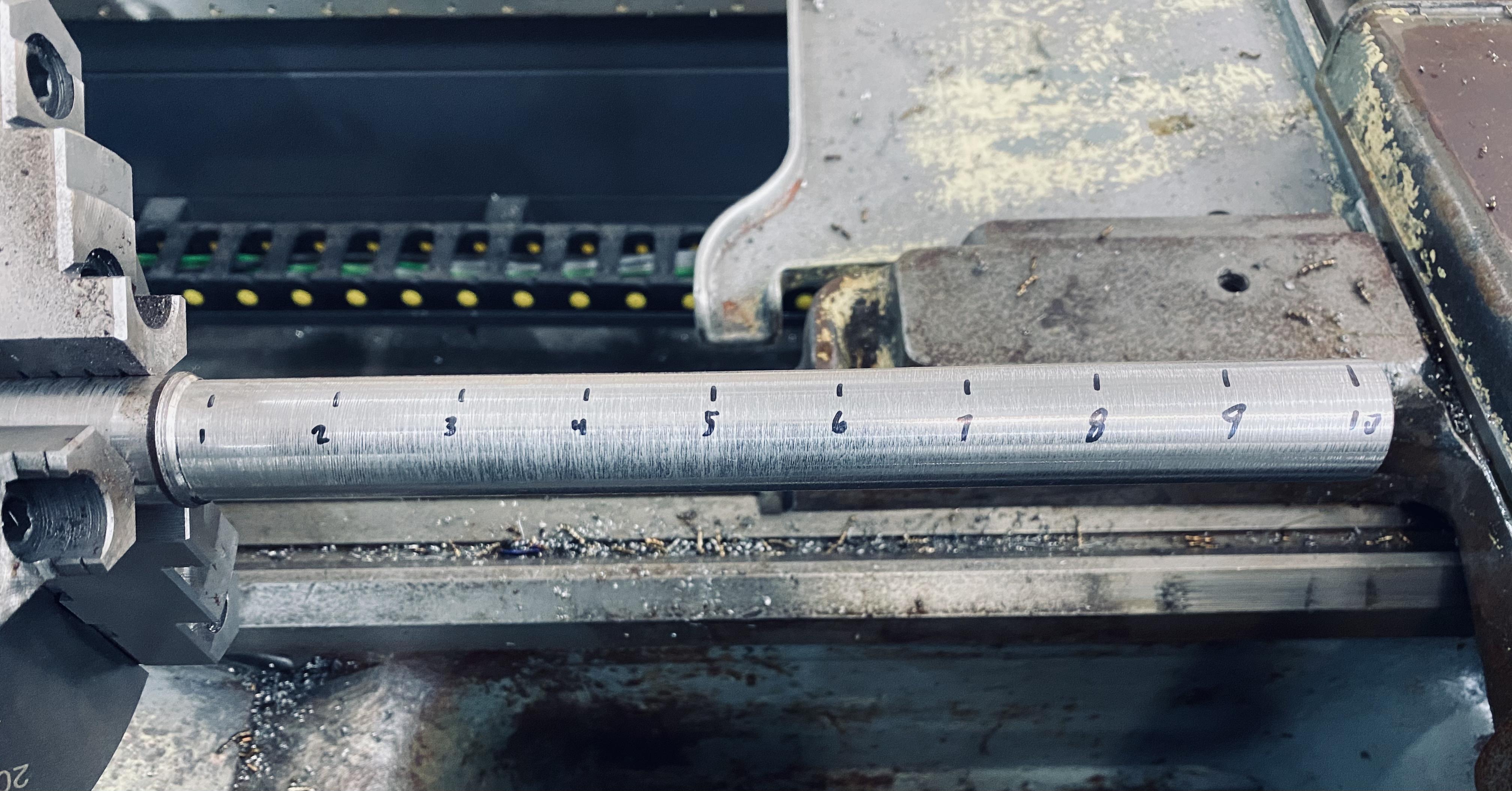

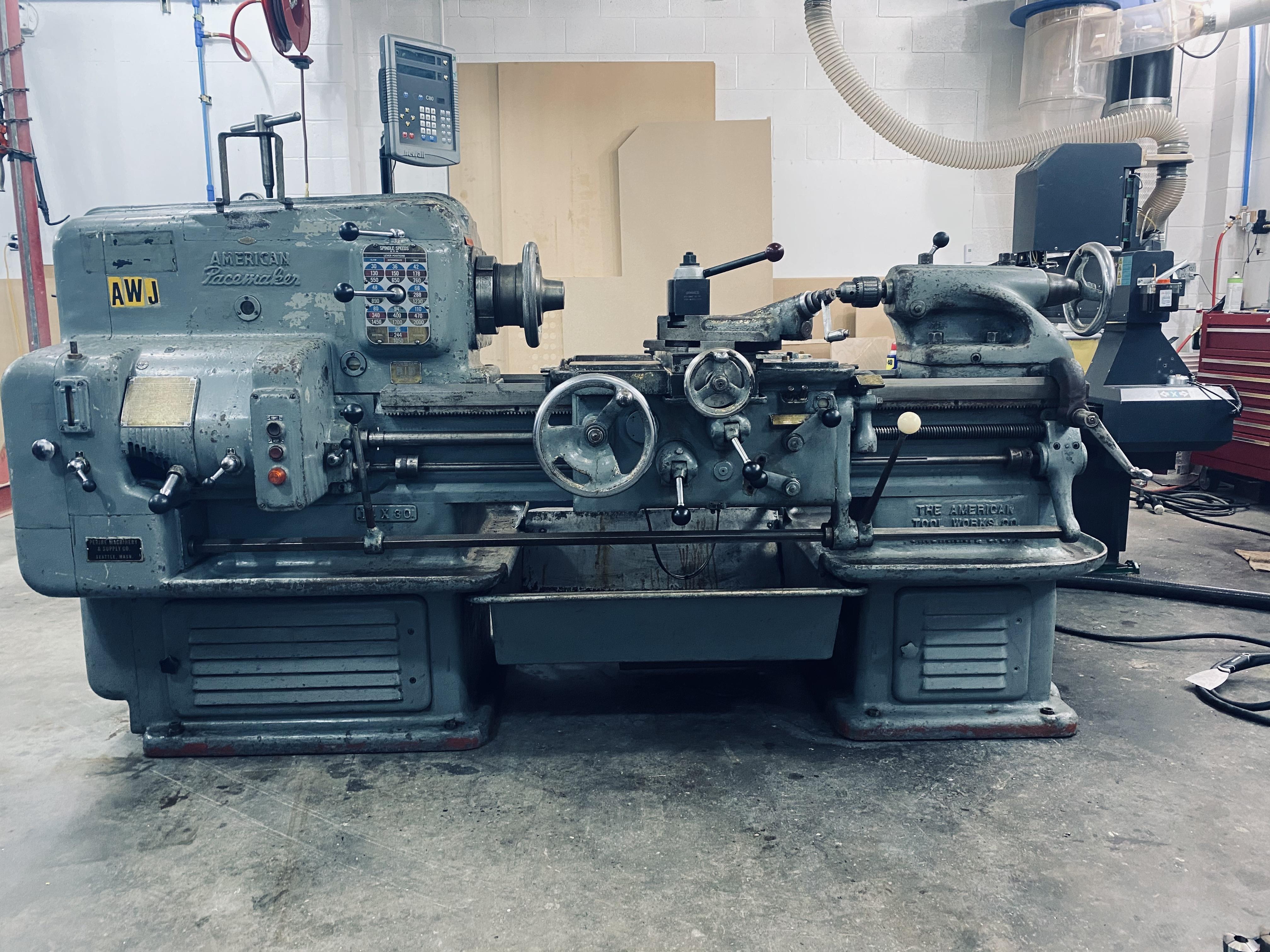

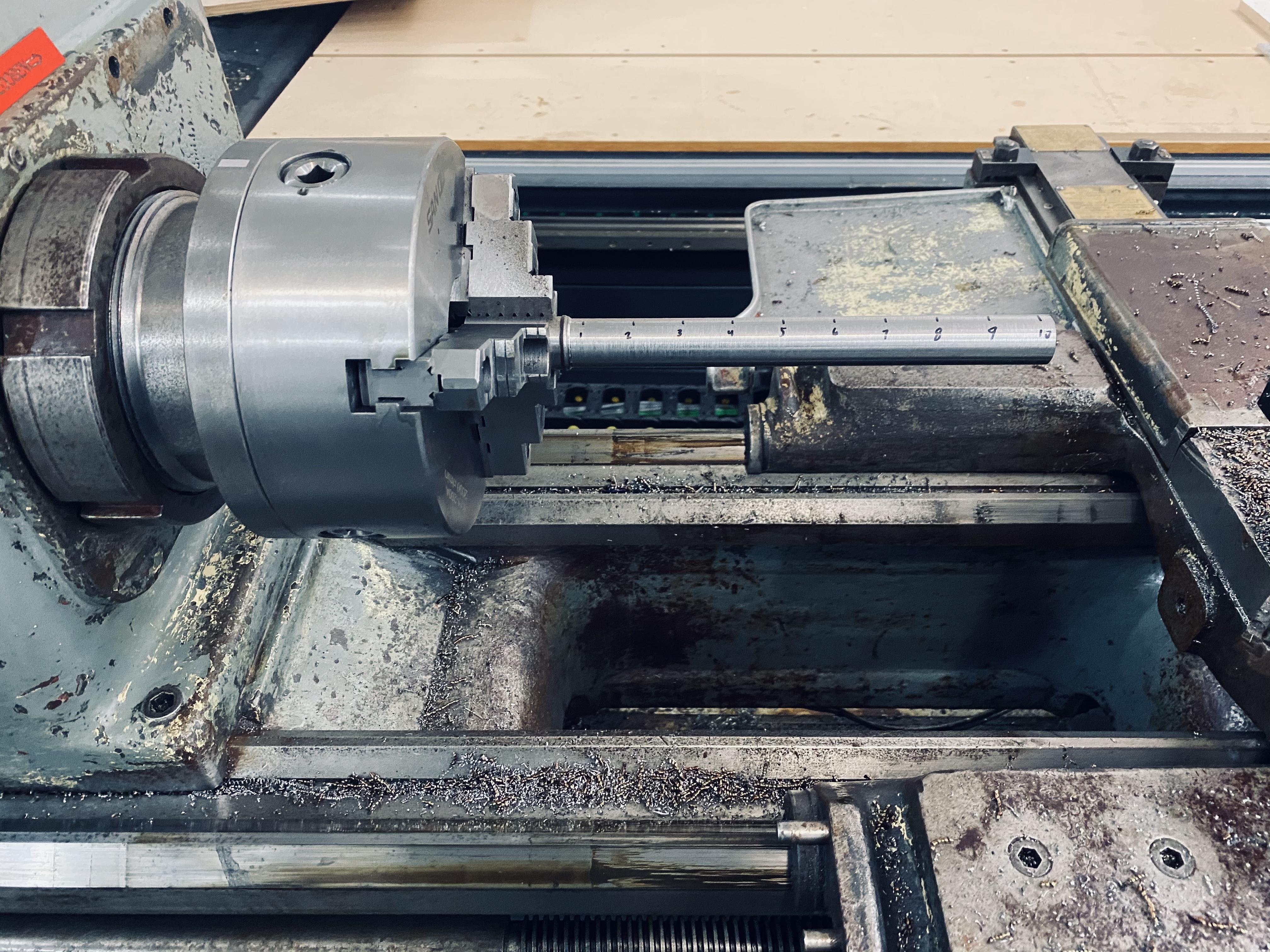

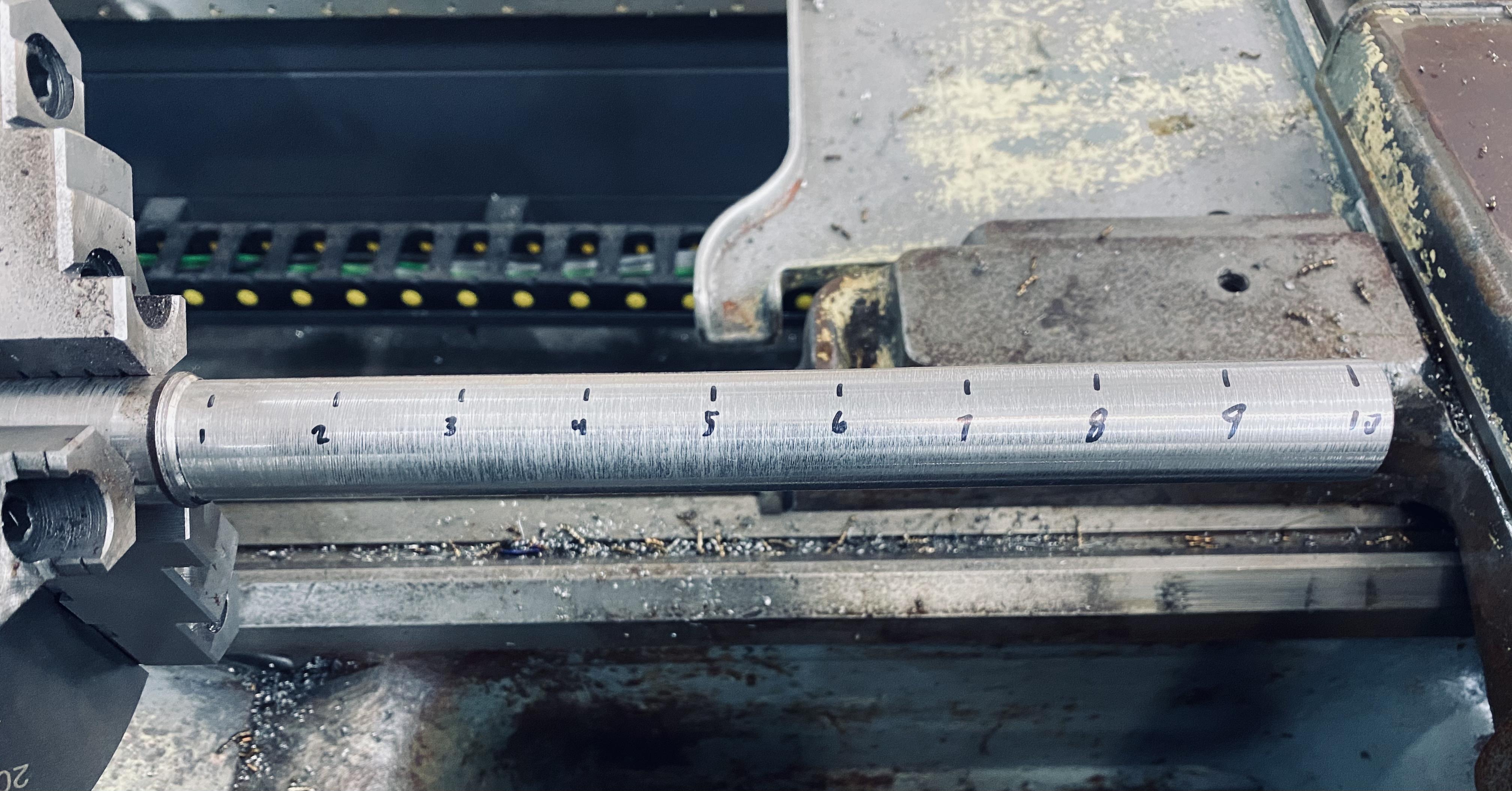

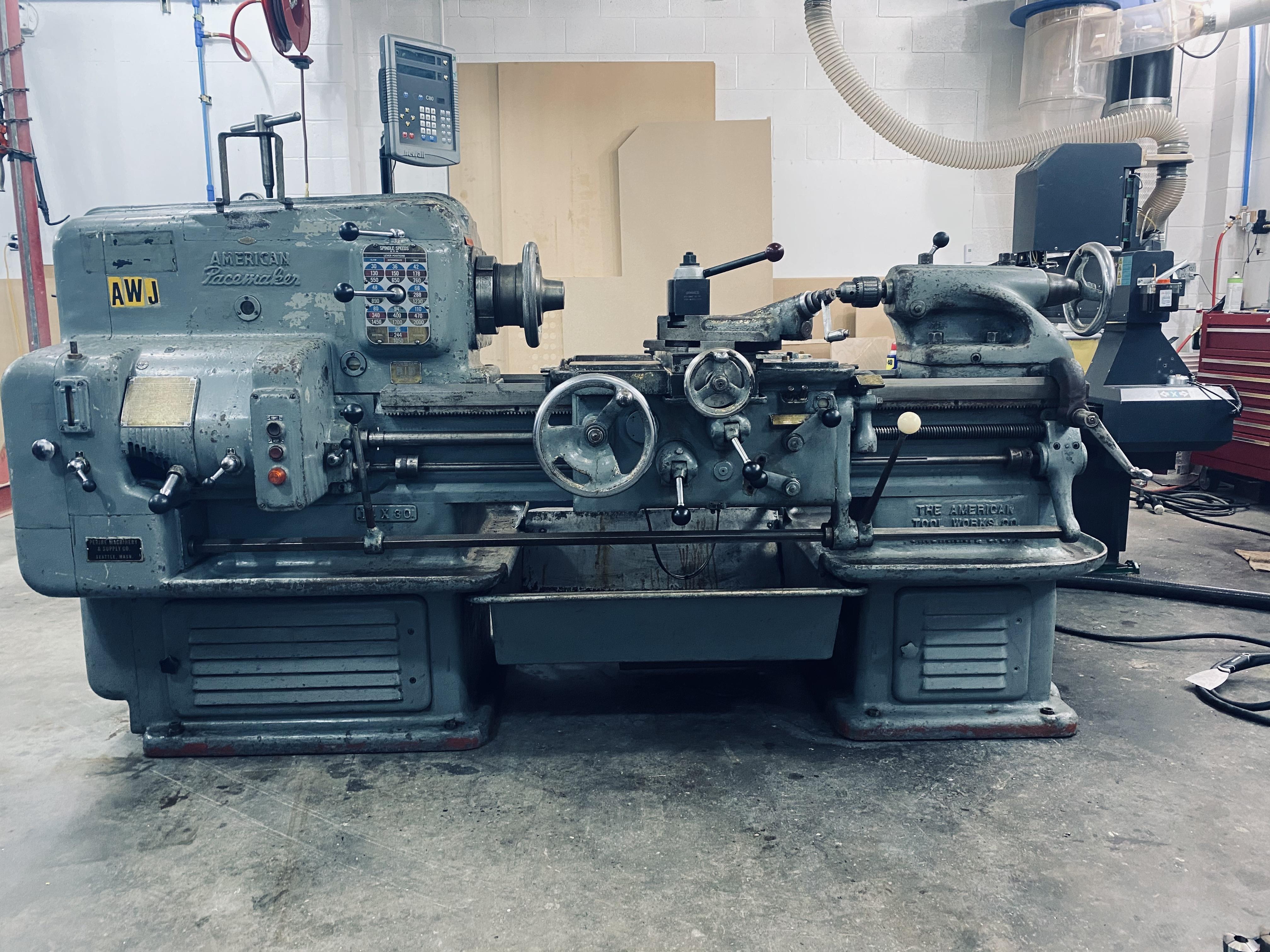

As the subject says, I am setting up my new to me 1953 American Tool Works Pacemaker 14x30 lathe. I brought it home a few weeks ago. Finished installing the rotary phase converter and get it into it's current final resting place. I was able to level the lathe under one graduation on my Starrett 98's in both directions. I turned a hot rolled bar to see how things look. I got the best surface finish I felt I could out of it. The bar was about 1.1" when I started. The final pass was very light with a slow feedrate.

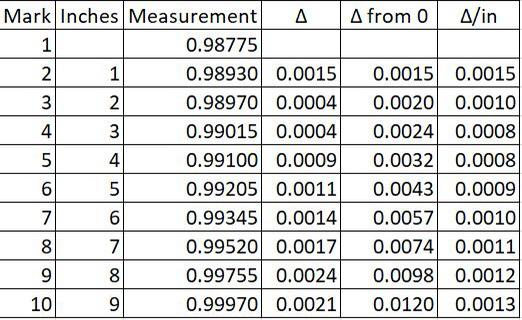

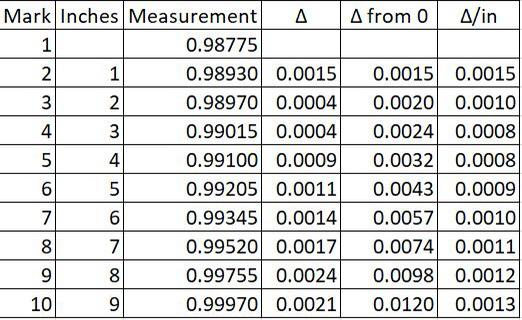

Results:

I’m thinking this is plenty good for a starting point on such an old machine. I welcome feedback. I have some nicer material I can turn for testing. The hot rolled was just what I picked up.

Results:

I’m thinking this is plenty good for a starting point on such an old machine. I welcome feedback. I have some nicer material I can turn for testing. The hot rolled was just what I picked up.

Last edited: