Hey guys, I think someone cut down the 1/2" diameter steel rod that the 4 step pulley and two step larger pulley ride on. The large pulley that the motor pulley turns barely clears the cotter pin that holds in the countershaft handle rod in the armature. My question is, what grade of steel should I use if I wanted to make a longer, 1/2" pulley shaft? W1, O1, mild steel, does it matter? does it need to be hardened? Thank you! -John

-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Counter Shaft Pulley Rod - Steel Type

- Thread starter JRT

- Start date

- Joined

- Jun 7, 2013

- Messages

- 10,142

Likely CRS would be fine.

I can get that pretty easy. I can also get W1 or O1 if its a better choice. Just thought I'd ask. Any clue what the factory ones were made of?... all of the steel "shafts" in the Counter Shaft for that matter. Thanks. -John

- Joined

- Jun 7, 2013

- Messages

- 10,142

being as they were low end machines and low powered,, it is doubtful that anything special was used for countershafting.

- Joined

- Sep 5, 2013

- Messages

- 3,214

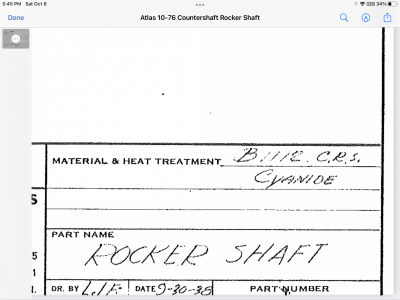

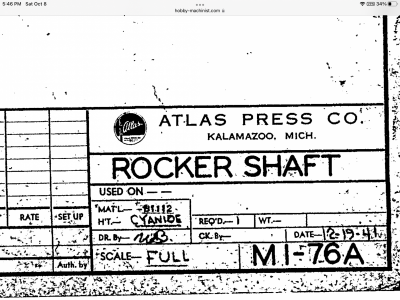

I don’t see any drawings for the countershafts themselves in our Downloads section, but we do have at least two for the rocker shaft on the 618 as well as 10” lathes. Both materials are called out as “B1112” with a cyanide heat treat. Maybe that helps you or maybe not.Any clue what the factory ones were made of?... all of the steel "shafts" in the Counter Shaft for that matter.

-frank