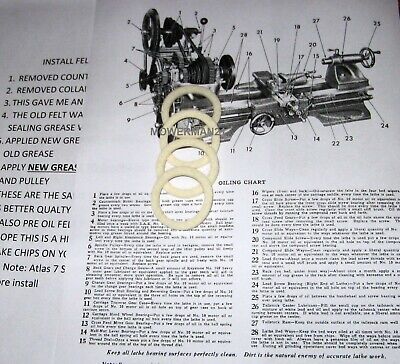

Cutting a few home made felt washers previously I turned up two hollow tubes for the inner & outer diameters putting a cutting edge on them with a wetted diamond impregnated nickel sharpening file as they turned in the lathe . Ensure the tubes are exactly the same length .

One cutter fits inside the other use a turned up in between the tubes spacer to give concentric spacing .

I then laid a square of thick medical felt on a bit of thick marine ply and used a 2 & 1/2 pound lump hammer to wallop the two tubes into the felt . Ended up changing the plywood out for a 6 inch square of thick conveyor belting . As it gave a better cut out .

I had to use a surgeons scalpel with curved blade on a couple of the washers to free them off the felt as the cutters hadn't quite cut right through the felt.

You can easily make your own " O " rings out of round butyl or silicone rubber see ebay number 281287811353for the general idea ) . Buy a small hank of the diameter of rubber needed ( I used to have half dozen common diameters 1,2,5, 6, 8 & 10 mm in my workshop )

Work out the pi x D to get the length needed for the correct size fit . Remember if it sits in a recess it will not be the maximum diameter of the shaft but the diameter at the groove depth .

Cut it dead square & to length with a craft knife at both ends as follows :-

Make a V cut the same width as the diameter of the rubber in the end of some 1/2" thick by about 2 inch wide oily plastic , wood or aluminium etc. Then accurately make a 90 degree vertical cut across it in the middle & at right angles with a fine junior hacksaw blade , make it deeper than the Vee .

Getting the length with square cut ends .

Lay the cord in the Vee to cut the first end at the cross cut slot using the craft knife , measure it off cut it to length again using the fine cross cut as the blade guide to get the ends square Check it has been cut to correct length to length . Now't worse then making a an O ring that is too big

Spot both ends with a small dot of super glue on both of the round faces . Now put them back in the Vee to align them perfectly ….pushing the ends together firmly but not overly hard , keep it in place continuously at the same pressure for 40 seconds . If it takes lift it off and lay the ring flat for an hour or more to fully cure .