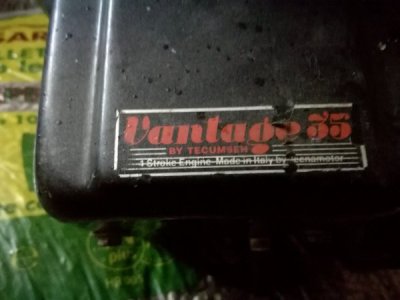

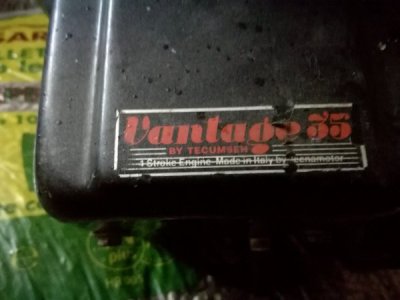

Last sunday i visited a tool/flea market and bought this lawn mower engine. You can read the label, is a Italian copy of 3,5 hp tecumseh engine, i've changed the oil, checked it has strong spark, new spark plug fresh gasoline, and then i tryed and start it, it kicks back, also i heard couple of loud pops from the exhaust, the flywheel is aluminium and it doesn't have blade, i've heard on some engine blade acts like a flywheel is this the case here and can i turn this engine and use it i vertical configuration without taking it apart ?