- Joined

- Feb 17, 2013

- Messages

- 4,407

Hmmmm ... Now you've got me to thinkin'! I'ts been a couple years since I took that photo. I'm sure it was a half-inch (nominal) tool bit I used, but I don't recall measuring it at the time. I have a different G4000 (9x20) now, and all my ½" bits are in Oregon with my other (larger) lathe. I'm here in Arizona for the winter.yes but it obviously depends upon the thickness of the tool bit.

On my lathe half inch tools can only be used with the AXA at 90 degrees to the compound or 45 degrees to the compound to allow the tool bit holder to drop that little bit further to get them on centre.

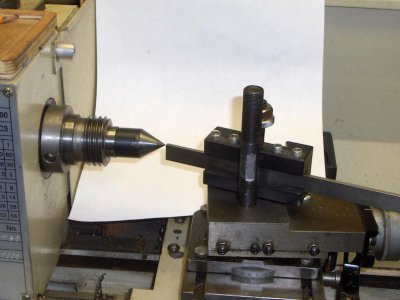

So just to verify things, I dug out a piece of low carbon ground bar, 0.502" tall, and secured it in a tool holder. Then I placed the tool holder directly on the top surface of the compound, and a piece of white paper in the background, as shown in the first photo:

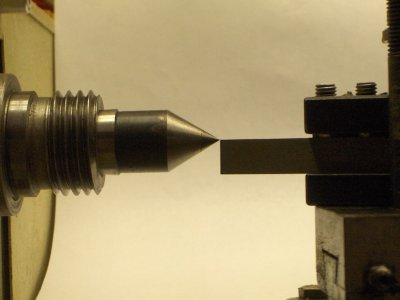

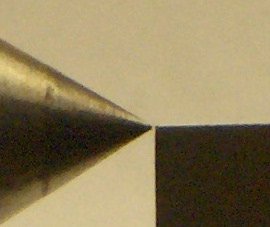

Got the camera level with the axis of the lathe and snapped the second photo. Third photo is a close-up of the ends of the spindle center and the ½" bar.

It does indeed look like the axis of the lathe is just a hair higher than the top of the ½" bar. So I must agree that the actual size of the "nominal" ½" lathe bit can become a factor. I don't know how exact they make ½" lathe tools. And then again, I wonder just how standardized the tool holders from different vendors are. What I used for the photos was a Phase II.

It does indeed look like the axis of the lathe is just a hair higher than the top of the ½" bar. So I must agree that the actual size of the "nominal" ½" lathe bit can become a factor. I don't know how exact they make ½" lathe tools. And then again, I wonder just how standardized the tool holders from different vendors are. What I used for the photos was a Phase II.I suppose if there were a problem, you could get around it by skimming just a hair off the bottom of the tool holder.

I'd mill (or grind or sand?) a bit from the bottom of the tool holder before milling on the compound. I think the compound is pretty weak already, and there's about .44" of steel below the tool slot on an AXA holder. Even if you gobbled off .060", you'd still have a lot more more meat below the tool than there is on a 0XA.Sounds like the AXA could be limiting. Would the OXO be the better choice? Could you not mill down the top of the compound to get the QTCP lower? Is there enough meat to do that? Oh yeah, I am only thinking aobut 1/2" tooling.