- Joined

- Sep 21, 2017

- Messages

- 117

Hmm, well the GFI is tripping immediately. The rotor doesn't budge at all, just 'bam' and the GFI faults as soon as I plug it in.Jacque beat me to it- the motor may have enough "normal" leakage such that using it with a GFI is not possible.

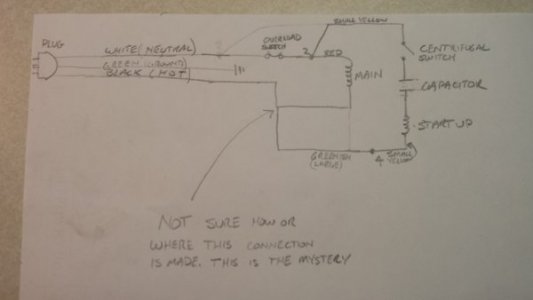

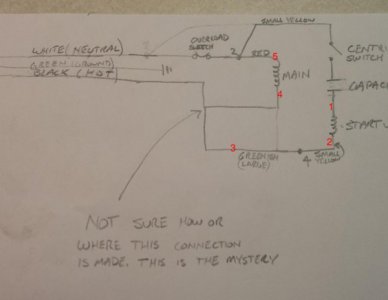

Here's a sketch of the wiring. It's crude, but should work as a sounding board.