- Joined

- Dec 30, 2022

- Messages

- 40

Hey all,

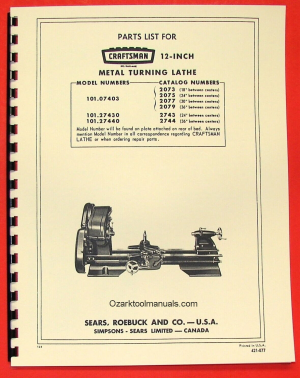

Just picked up a Craftsman 101.07403. The serial number plate on the tail end is marked "12L 042824".

Can anyone help me get a date on this lathe? I had read in some other posts that dates should be stamped on the Timken bearings. When I pulled the spindle I see "3 154" and "3 156" engraved on the outer race. In another post I saw them engraved with a day-month-year code, so I'm not sure how to interpret 154/156.

I don't know much about craftsman lathes, I grabbed this one off of craigslist because the price seemed decent and I wanted a bit of a restoration project. I'm sure there will be more questions to follow as I try to figure this thing out, so any and all help is appreciated.

Just picked up a Craftsman 101.07403. The serial number plate on the tail end is marked "12L 042824".

Can anyone help me get a date on this lathe? I had read in some other posts that dates should be stamped on the Timken bearings. When I pulled the spindle I see "3 154" and "3 156" engraved on the outer race. In another post I saw them engraved with a day-month-year code, so I'm not sure how to interpret 154/156.

I don't know much about craftsman lathes, I grabbed this one off of craigslist because the price seemed decent and I wanted a bit of a restoration project. I'm sure there will be more questions to follow as I try to figure this thing out, so any and all help is appreciated.