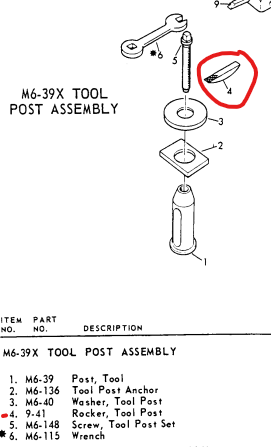

I recently bought this lathe and I'm getting it cleaned up right now. It came with a decent amount of tooling and accessories but one thing it is missing is the tool post rocker, I imagine it's sitting lost on one of the previous owners' shop floor right now.

Does anyone know where I might buy one of these relatively cheaply? All I can find online is around $30 shipped and that seems high to me. The plan is to eventually get a QCTP but I wanted to get a few hours on this machine at least before I commit to spending more money.

Alternately, my plan is to mill one out but I only have aluminum and bronze on hand right now. Am I wasting my time by not making this out of steel?

Thanks,

Greg

Does anyone know where I might buy one of these relatively cheaply? All I can find online is around $30 shipped and that seems high to me. The plan is to eventually get a QCTP but I wanted to get a few hours on this machine at least before I commit to spending more money.

Alternately, my plan is to mill one out but I only have aluminum and bronze on hand right now. Am I wasting my time by not making this out of steel?

Thanks,

Greg