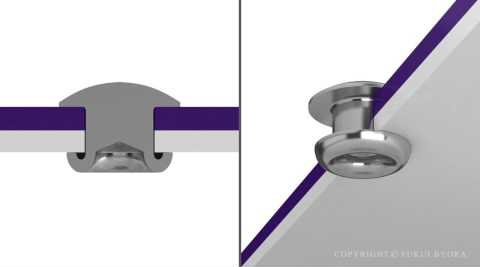

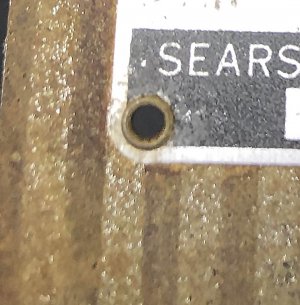

In the first & second photographs, What are these types of rivet or fastener hold the name tag in place? The donut-shaped rivet is identical on both sides as there's very little clearance between the backside of the metal and the electric motor. If replacing it with something identical isn't practical is there an alternative?

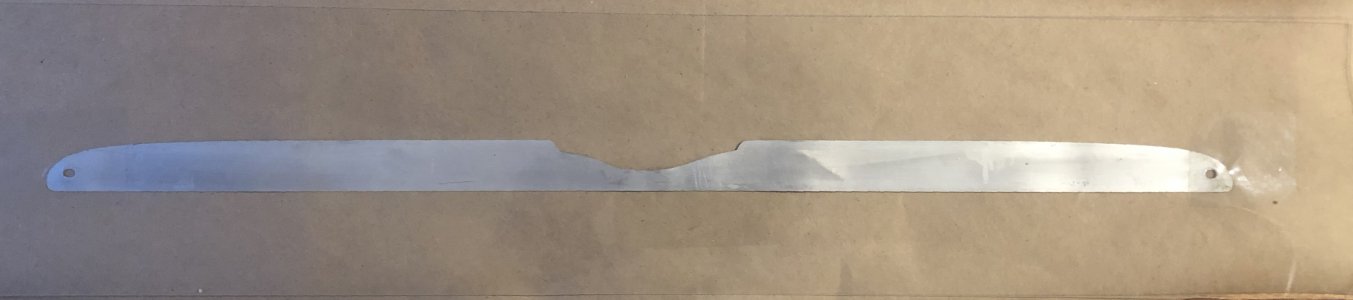

Is there a way of producing the stripes on the sheet of metal?

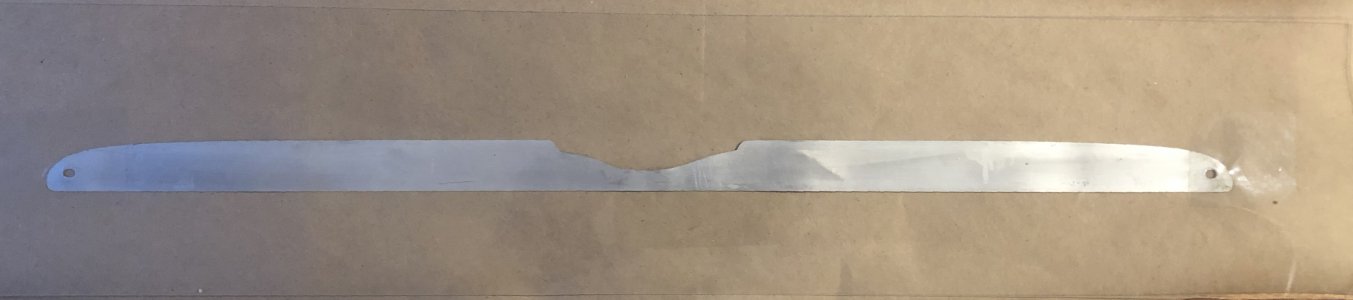

The third photograph, trim metal around top of the drill press. Somebody who knows fusion 360 or other software, willing to make a file for anybody to have free of charge, to reproduce it.

Is there a way of producing the stripes on the sheet of metal?

The third photograph, trim metal around top of the drill press. Somebody who knows fusion 360 or other software, willing to make a file for anybody to have free of charge, to reproduce it.

Last edited: