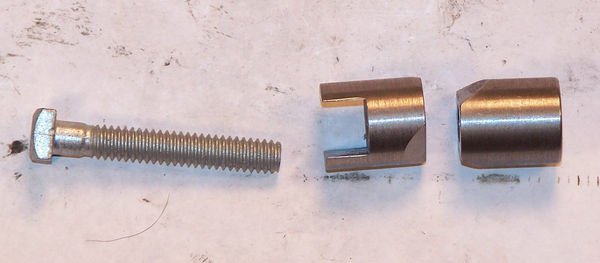

I just added a Craftsmen 101.07301 to my tool list. It was not assembled when I got it. The motor was not fastened to the bench, and no belts, the countershaft was not attached to the bench. Everything seems to be complete but will have to be assembled. I am starting with the tail stock and found the ram had a burr on the guide slot underneath and was very tight when moving. I have polished that out and it is like butter now. The ram lock tightens and holds, but will not release when you unscrew it. I am soaking in oil, WD, and Liquid Wrench hoping to break it free. I have searched for information about removing the m6-44 and m6-45 (sleeve and lock) and what I have found has conflicting information. One post says to take one out the top and drive the other out the bottom and the other post says they come out the top. The bolt does not come out of the tailstock because it looks like it is a bit long, so I don't think going out the bottom is an option. I don't want to mess anything up so I'm hoping someone can tell me for sure how to fix the locking mechanism on the tailstock.

Gary

Gary