- Joined

- May 27, 2016

- Messages

- 3,480

It seems obvious to me, but I take it that "micrometer carriage stop" and "threading" are not concepts that should ever feature in the same sentence. My search does not yield anything much about power feed crashes involving hard stops.

Of course, the survival sense in the bones is yelling that, if you are threading, you pay attention, and let go with the lead screw half-nuts pretty darn smartly, or start from the left end!

So how often do we hear of a lathe driving the carriage into a micrometer stop - or for that matter, into any other part of the lathe? Has anyone ever simultaneously reworked their chuck and toolpost?

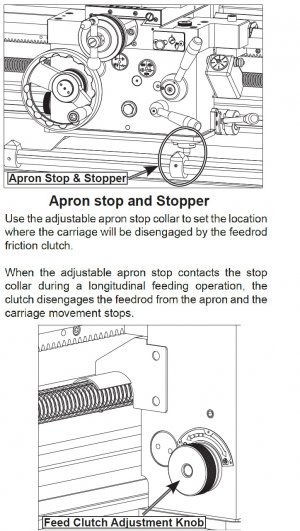

This is just background to me thinking that a limit switch arrangement might be used to stop things if the saddle gets to places it should not go. I also am imagining that a micrometer carriage stop might reasonably have a 2-stage feature which would push on some arrangement on the apron to automatically take out the power feed (stage#1) while still allowing the carriage to be manually moved a little further up to the intended mechanical stop (stage#2).

OK - so I am somewhat a beginner. Maybe the fancier lathes have something that does this?

Of course, the survival sense in the bones is yelling that, if you are threading, you pay attention, and let go with the lead screw half-nuts pretty darn smartly, or start from the left end!

So how often do we hear of a lathe driving the carriage into a micrometer stop - or for that matter, into any other part of the lathe? Has anyone ever simultaneously reworked their chuck and toolpost?

This is just background to me thinking that a limit switch arrangement might be used to stop things if the saddle gets to places it should not go. I also am imagining that a micrometer carriage stop might reasonably have a 2-stage feature which would push on some arrangement on the apron to automatically take out the power feed (stage#1) while still allowing the carriage to be manually moved a little further up to the intended mechanical stop (stage#2).

OK - so I am somewhat a beginner. Maybe the fancier lathes have something that does this?