- Joined

- Mar 26, 2018

- Messages

- 8,412

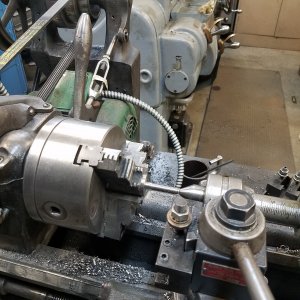

I think we are all a bit respectful of the "crash" potential while threading. I know I am.

I learned by incident that I have the clutch in the apron almost exactly like the picture mksj posted.

I was threading and got to the end or under cut section and the thread or half nut lever was stuck.

The QCTP hit the chuck outside the jaws so I didn't have a bad crash. Thanks to the clutch I had very little damage.

I stepped on the brake almost immediately.

After reviewing what happened, my under cut was not adequate in size or depth.

Lesson learned.

I learned by incident that I have the clutch in the apron almost exactly like the picture mksj posted.

I was threading and got to the end or under cut section and the thread or half nut lever was stuck.

The QCTP hit the chuck outside the jaws so I didn't have a bad crash. Thanks to the clutch I had very little damage.

I stepped on the brake almost immediately.

After reviewing what happened, my under cut was not adequate in size or depth.

Lesson learned.