- Joined

- Feb 1, 2015

- Messages

- 9,621

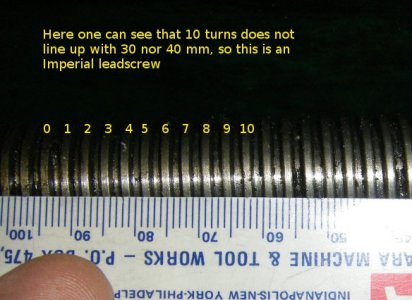

I did try to measure metric threads on the less screw, nothing really lined up. hoe should I be measuring it tho?

When I measured the 8tpi on the lead screw, it was almost dead nuts 8 teeth I'm the inch on the ruler

With a lead screw pitch of 8 tpi, you should have a 16 tooth gear on the thread dial. This will give you 2" of travel of the carriage for one revolution of the thread dial. Everything should be OK then. Apparently either the PO replaced the OEM gear with one from a metric set or the wrong gear was installed during manufacturing.

An 8 tpi lead screw would be very close to a 3mm metric pitch. You can tell the difference by measuring the distance traveled by the carriage through 10 revolutions of the thread dial. The distance for your setup with an 8 tpi lead screw would be exactly 17.5". For a 3mm pitch metric lead screw, the distance would exactly 420mm or 16.54". If you do have an 8 tpi lead screw, you just need to get or make the 16 tooth gear.