- Joined

- Nov 14, 2016

- Messages

- 3,005

I have the same Taig ER16 chuck and it fits my Sherline without issue. I've seen others using it as well, and have never heard there was a need to modify it.

Usually the Taig lathe is the one that needs to adjust for Sherline hardware. Taig on Sherline usually works as is, but Taig users will often fit a thin spacer (washer) onto the Taig spindle when using Sherline tooling since the Sherline tooling is made for a shorter spindle.

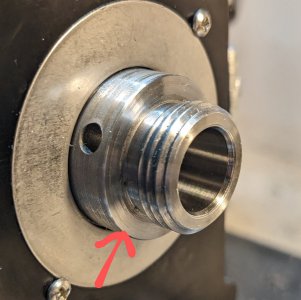

There may be something weird going on with your chuck.

Usually the Taig lathe is the one that needs to adjust for Sherline hardware. Taig on Sherline usually works as is, but Taig users will often fit a thin spacer (washer) onto the Taig spindle when using Sherline tooling since the Sherline tooling is made for a shorter spindle.

There may be something weird going on with your chuck.