- Joined

- Feb 9, 2017

- Messages

- 5,308

It seems my shop is full of rabbit holes. I was trying to make a slip fit that was .747” ID and as I got close I thought now would be the perfect time to get out this cool set of L.O. Beard adjustable hones I picked up a couple of years ago. The set has 3/4”, 7/8” and 1”. I would have thought they would have been able to start under and adjust to something over each size. Unfortunately it seemed the 3/4” started at .750 and I don’t have a 3/4” adjustable reamer. Double drat. Triple drat that most of the refills I miraculously found local had the fine versions well used. With one on the 3/4” peeling on the end. I got to thinking how would I refurb the worn ones? They seem to be crocus cloth or emory paper wrapped over then with my goggles I realized the edges of the metal backing were crimped over.

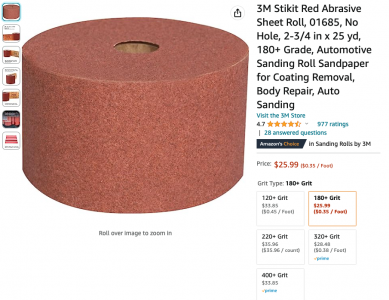

I looked it up and the info I saw said you’d need to use epoxy to hold the new stuff to the metal backing. But it occurred to me the refills I put on my disk sander are just stuck on and they seem to stay out for years. I have some 3M sticky backed aluminum oxide paper. Maybe I don’t even have to bend down the little edges to hold sticky back paper once the old stuff is cleaned off? Anybody ever tried something similar?

I looked it up and the info I saw said you’d need to use epoxy to hold the new stuff to the metal backing. But it occurred to me the refills I put on my disk sander are just stuck on and they seem to stay out for years. I have some 3M sticky backed aluminum oxide paper. Maybe I don’t even have to bend down the little edges to hold sticky back paper once the old stuff is cleaned off? Anybody ever tried something similar?