Just wondering if anyone has come up with a way to access the cross slide gib adjustment screws with a glass slide installed? I know moving it to the left side is an option, but that comes with it’s own set of issues (can’t use steady rest, damaged by chuck, chips, etc). I’ve thought about using hex bolts instead of set screws and using a wrench to make adjustments, but there’s not much clearance. Any ideas would be appreciated.

-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Cross slide gib adjustment with DRO scale

- Thread starter MSD0

- Start date

- Joined

- May 16, 2015

- Messages

- 162

Some pics of the setup would help alot

A

Alan H.

Forum Guest

Register Today

Are you really talking about gib adjustment or the cross slide lock? The gib adjustment screws are often on the ends and not on the side of the cross slide. However the lock often gets covered with a DRO scale.

Yes, a photo will help.

Yes, a photo will help.

- Joined

- Jun 12, 2014

- Messages

- 4,814

Per Alan's remark I believe you are referring to the cross slide lock. A number of solutions by different HM members.

http://www.hobby-machinist.com/threads/installing-dro-on-pm-1340-gt.48653/

http://www.hobby-machinist.com/threads/another-pm1340gt-build.52267/

http://www.hobby-machinist.com/threads/ghb1340-dro-install-carriage-scale-mounting.52444/

http://www.hobby-machinist.com/threads/dro-advise.46301/

I use a low profile bolt on friction lock on the headstock end. It uses a heavy steel plate with a fine threaded Bronze lock. I added a neoprene gasket between the plate and the cross slide to keep the chips out.

http://www.hobby-machinist.com/threads/installing-dro-on-pm-1340-gt.48653/

http://www.hobby-machinist.com/threads/another-pm1340gt-build.52267/

http://www.hobby-machinist.com/threads/ghb1340-dro-install-carriage-scale-mounting.52444/

http://www.hobby-machinist.com/threads/dro-advise.46301/

I use a low profile bolt on friction lock on the headstock end. It uses a heavy steel plate with a fine threaded Bronze lock. I added a neoprene gasket between the plate and the cross slide to keep the chips out.

- Joined

- Aug 15, 2013

- Messages

- 2,114

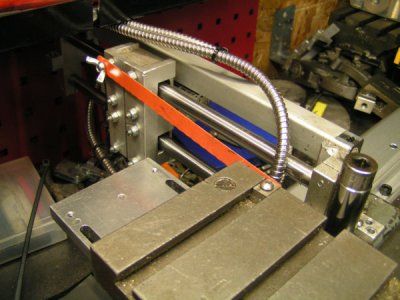

Yeah, sorry should have been more specific. It’s a PM1127VF-LB with the glass scale installed in the same location.OP doesn't say what machine he has, but I'm under the impression he is talking about a set up similar to this pic, where the cross slide gib adjustment screws are covered by the scale. But, keep in mind, I was wrong once before.

View attachment 249983

- Joined

- Feb 1, 2015

- Messages

- 9,615

Just wondering if anyone has come up with a way to access the cross slide gib adjustment screws with a glass slide installed? I know moving it to the left side is an option, but that comes with it’s own set of issues (can’t use steady rest, damaged by chuck, chips, etc). I’ve thought about using hex bolts instead of set screws and using a wrench to make adjustments, but there’s not much clearance. Any ideas would be appreciated.

Cross slide gib adjustment on m any smaller lathes is done by 3 or 4 dog point set screws with locking nuts.

On my G0602, made a mounting bracket which permitted access to the lock nuts. Because I didn't want to further limit tailstock travel, I opted for having to remove the scale (4 screws) and cover (4 screws. Not a terrible inconvenience since gib adjustment is an infrequent activity. Details here.http://www.hobby-machinist.com/threads/another-lathe-dro-install.34106/

In the your case, the scale could be mounted on a plate mounted on standoffs which would permit access to the adjustments if modified hex head screws were substituted for the OEM set screws. Tailstock travel would suffer but most likely it would be an acceptable compromise.

Thanks, I’ll give the hex head screws a shot. I already have standoffs, so I should have enough room.Cross slide gib adjustment on m any smaller lathes is done by 3 or 4 dog point set screws with locking nuts.

On my G0602, made a mounting bracket which permitted access to the lock nuts. Because I didn't want to further limit tailstock travel, I opted for having to remove the scale (4 screws) and cover (4 screws. Not a terrible inconvenience since gib adjustment is an infrequent activity. Details here.http://www.hobby-machinist.com/threads/another-lathe-dro-install.34106/

In the your case, the scale could be mounted on a plate mounted on standoffs which would permit access to the adjustments if modified hex head screws were substituted for the OEM set screws. Tailstock travel would suffer but most likely it would be an acceptable compromise.

- Joined

- Oct 21, 2017

- Messages

- 504

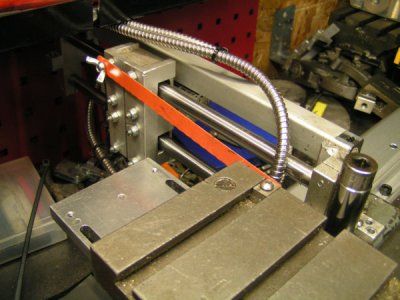

When fitting my lathe DRO I wasn't happy with any of the suggested options for the Myford Super 7.

I built a linear slide from cheap rods, mounts and linear bearings, mounted the scale to that and then hung it outboard at the back on a bracket with a link rod (hacksaw blade with ground slots) to the cross slide -

It looks a little "Heath Robinson"/"Rube Goldberg" but it's very functional and repeatable.

I built a linear slide from cheap rods, mounts and linear bearings, mounted the scale to that and then hung it outboard at the back on a bracket with a link rod (hacksaw blade with ground slots) to the cross slide -

It looks a little "Heath Robinson"/"Rube Goldberg" but it's very functional and repeatable.

Thinking outside the box. I like that!When fitting my lathe DRO I wasn't happy with any of the suggested options for the Myford Super 7.

I built a linear slide from cheap rods, mounts and linear bearings, mounted the scale to that and then hung it outboard at the back on a bracket with a link rod (hacksaw blade with ground slots) to the cross slide -

View attachment 250019

It looks a little "Heath Robinson"/"Rube Goldberg" but it's very functional and repeatable.