- Joined

- Jan 12, 2019

- Messages

- 12

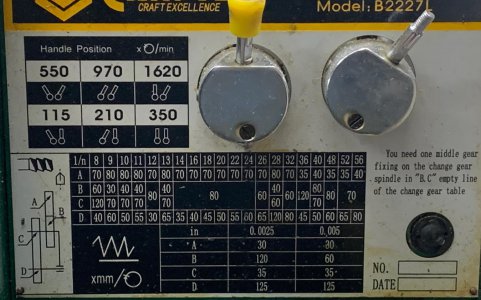

Having trouble decoding this gear chart. I'm considering making an ER40 chuck to fit on a 5" plate-style spindle, and it requires an M50 x 1.5 thread. My Craftex B2227L lathe's instruction manual promises that it can do metric threading. I don't see from the chart what gears to use... Any ideas? (photo attached)