- Joined

- May 13, 2021

- Messages

- 26

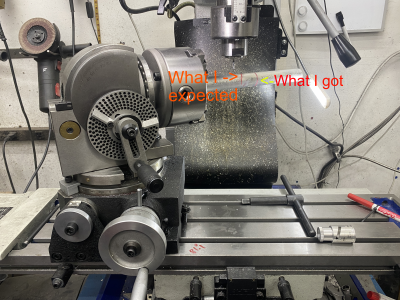

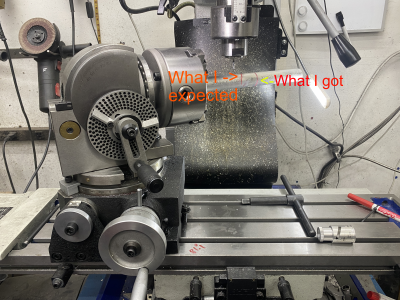

I need to cut 180 degree spiral at a 20 degree angle. In my head, I thought I have what I need, but when I practiced with a sharpie, I see the flaw in my thinking. My convoluted method will just cut normally across the circumference and not at an angle. Is there a way to cut a spiral groove in round stock or tubing that doesn't require a lathe attachment?

(I didn't even notice until I posted the pic, but that little cylinder on the lower-right of the table is what I'm trying to mimic)

(I didn't even notice until I posted the pic, but that little cylinder on the lower-right of the table is what I'm trying to mimic)