- Joined

- Oct 7, 2020

- Messages

- 2,116

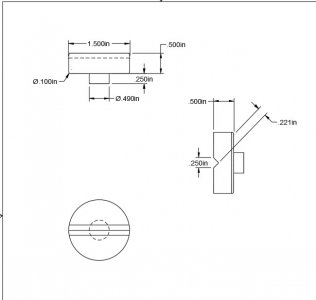

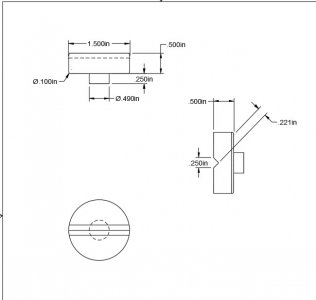

I guys, I'm in the process of making a couple of machinist jacks. I'm wondering how to cut the groove in the top part of the jack. I have an idea on how to do it but I'm a little unsure of how exactly I'm going to get it cut in the center.

I have a PM-935 Mill, and my idea is to place a 3" x 1.5" bar in the vice and tilt the head of my mill to 45° and cut the groove. That's about as far as my idea goes. Since the mill head would be tilted, how would I find center? I could measure it out with my calipers and scribe the center line and then just line up the edge of the end mill. At that point move the table up until I get to the depth that I want. I think that would work but it seems a little by guess by golly.

I have included a photo of my drawing; I hope that help.

I have a PM-935 Mill, and my idea is to place a 3" x 1.5" bar in the vice and tilt the head of my mill to 45° and cut the groove. That's about as far as my idea goes. Since the mill head would be tilted, how would I find center? I could measure it out with my calipers and scribe the center line and then just line up the edge of the end mill. At that point move the table up until I get to the depth that I want. I think that would work but it seems a little by guess by golly.

I have included a photo of my drawing; I hope that help.