A

acourtjester

Forum Guest

Register Today

HI

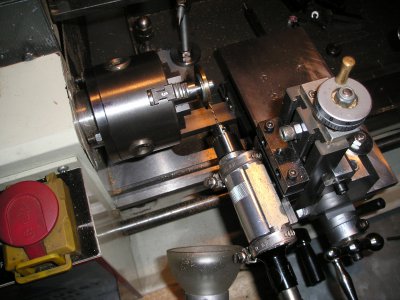

Here is a tool I developed to cut key slots in a shaft.

[video=youtube;eVgZol6Mfvo] http://www.youtube.com/watch?v=eVgZol6Mfvo [/video]

hav fun

Tom

Here is a tool I developed to cut key slots in a shaft.

[video=youtube;eVgZol6Mfvo] http://www.youtube.com/watch?v=eVgZol6Mfvo [/video]

hav fun

Tom

Last edited by a moderator: