I somewhat regularly find myself cutting shallow angles on my little band saw. By shallow, I mean in the range of 10-25 degrees. Until now I have just tried to clamp the stock (usually on its side) to the saw and cut it that way, but that is frequently very off of square and depending on how long the piece is, how wide, etc. it can't really be done. I did some googling and found some stuff like welded 90* "L" shaped pieces and such, but my issue is really how to cut these angles while securely fastening the work. I usually cut stuff between 1/4"-1/2" thick, which on edge and at shallow angles, makes it very tough to fixture. But I know you guys are pretty clever and must have something ingenious kicking around. Pictures would be awesome, but I'll take whatever I can get right now!

-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Cutting Shallow Angles On 4x6

- Thread starter Ripthorn

- Start date

- Joined

- Feb 1, 2015

- Messages

- 9,645

For shallow angles, I usually use the saw in a vertical position and hand feed. I very seldom use a saw cut as a finished surface, preferring to mill the surface for a clean face. The 4 x 6 horizontal band saws were never intended to be precision cutting machines. Their purpose is to cut off stock. They really don't offer a good opportunity to clamp short pieces

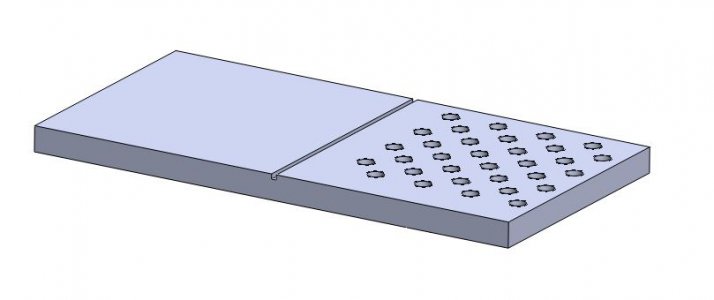

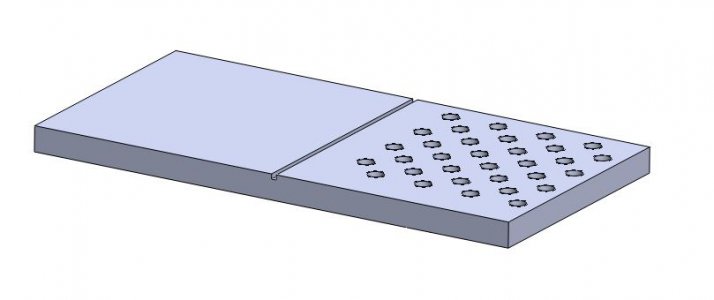

If you do enough shallow angle cuts, it may warrant making a plate to fit your saw where you can clamp from the outboard side. A piece of 1/2" x 5" x 12" relieved for the saw blade and upper blade guide and with a few strategically placed tapped holes would provide a nice "table" that will allow a variety of clamping schemes.

Bob

If you do enough shallow angle cuts, it may warrant making a plate to fit your saw where you can clamp from the outboard side. A piece of 1/2" x 5" x 12" relieved for the saw blade and upper blade guide and with a few strategically placed tapped holes would provide a nice "table" that will allow a variety of clamping schemes.

Bob

- Joined

- Feb 1, 2015

- Messages

- 9,645

Here is what I was talking about. The plate is held in the saw with your current vise and the you can fasten your work from the right using your mill step clamps. If you have repetitive work, you can clamp guides or fixtures as well. You can add as many or few holes as you want; go crazy. If you wish, you can add holes to the left side as well.

Bob

Bob

Just saw in a older HSM or MW an angle attachment that worked kinda like a scissor jack on it's side. You crank the angle in with a protractor place against the fixed jaw clamp the stock and saw. I think you can find the issue in their downloadable index. Looked pretty slick.