- Joined

- Dec 2, 2016

- Messages

- 234

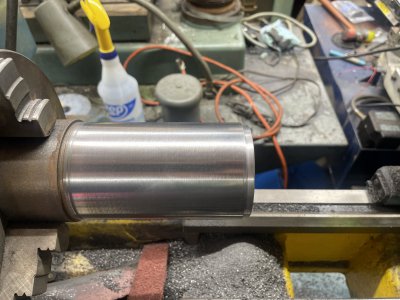

Looking to see if anyone has come into a rebuild with a similar setup. The picture below is of my 1954 TWN (German Triumph) Super Tessy Moped engine. When I got the bike it had been sitting since the mid 90's in a barn and was fully frozen. I tried about 3 months of heating and soaking to get the piston out. But in the meantime buggered up the sleeve as the piston was not budging.

I am currently remaking the sleeve and wanted to know what a good clearance is needed between the recessed bore in the head to the sleeve protrusion shown in picture. When the sleeve is in the cylinder it protrudes above the gasket surface into the head. I have it currently at spec. from what I pulled from the engine. which has about a .006" difference from counterbore in head to OD of sleeve protrusion. Should I close that up more or keep it as is?

Bike is 150cc bore is about 58mm. I have the OD of the sleeve machined and am fairly heavy on the ID of the sleeve. Thinking I'll see what I can get away with for any increase in bore diameter.

Would there be any benefit to having a machine shop give the combustion chamber more of a dome shape and fit a custom piston with a tad higher compression?

I am currently remaking the sleeve and wanted to know what a good clearance is needed between the recessed bore in the head to the sleeve protrusion shown in picture. When the sleeve is in the cylinder it protrudes above the gasket surface into the head. I have it currently at spec. from what I pulled from the engine. which has about a .006" difference from counterbore in head to OD of sleeve protrusion. Should I close that up more or keep it as is?

Bike is 150cc bore is about 58mm. I have the OD of the sleeve machined and am fairly heavy on the ID of the sleeve. Thinking I'll see what I can get away with for any increase in bore diameter.

Would there be any benefit to having a machine shop give the combustion chamber more of a dome shape and fit a custom piston with a tad higher compression?

Last edited: