-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Datum for Lathe Leveling

- Thread starter ddickey

- Start date

- Joined

- Nov 5, 2016

- Messages

- 1,419

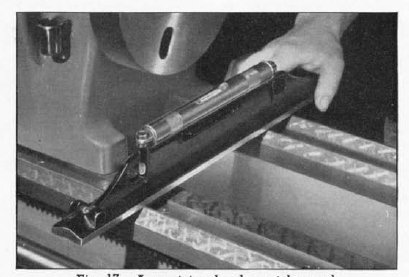

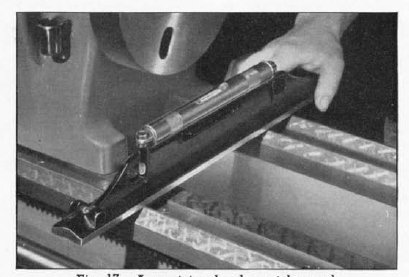

When I level my SB lathes I go off the top of the V ways. I have a 12" level that spans them. I mark where I'm going to repeatedly place the level with a marker and then very lightly hone the flats on the V way tops in this location to verify there are no high spots. The tops of the V ways should not have any wear at all since they shouldn't come in contact with the mating surfaces (there's a clearance there). Just make sure there are no bangs, burrs or git there.

I would never use the carriage and the flat ways can have a lot of wear on them.

My two cents,

Ted

I would never use the carriage and the flat ways can have a lot of wear on them.

My two cents,

Ted

- Joined

- Nov 5, 2016

- Messages

- 1,419

I've never read any spec that states that they are, but lathes being the machines that they are it only makes sense to me that they would be. Maybe some of the guys here that do way truing and scraping can offer some input in any written industry standards that may exist.

I would find it hard to believe that they wouldn't be.

Ted

I would find it hard to believe that they wouldn't be.

Ted

- Joined

- Nov 5, 2016

- Messages

- 1,419

Looks like I should have limited my answer to SB lathes... I also know that some lathes like Atlas have flat ways and if I remember correctly the LeBlond lathes we had at work had flat ways at an angle. Below is what I use for SB lathes. What brand lathe are you going to level? Per Mickey sounds likes some lathes with multiple V ways don't, by design, have them at the same height or at least I hope it was by design!

Ted

Ted

As long as you use the same position on each end it shouldn't matter. You're just making a comparison to determine bed twist....or maybe I'm not understanding what you're asking.I went out and put the level on the V's. I measured the distance to the flat way and the difference was significant.

No that's correct. You make a good point though.

I have a few issues. One is any adjustment I make to the leveling feet have little or no affect on cutting a taper. I've found I need to shim under the lathe feet.

The other issue is I'm trying to start that process with a level bed, then take some test cuts. I find I am only adjusting two feet exactly diagonal or opposite of each other. What's happening is I end up with only 2 feet on the floor. I don't know if that makes sense.

I have a few issues. One is any adjustment I make to the leveling feet have little or no affect on cutting a taper. I've found I need to shim under the lathe feet.

The other issue is I'm trying to start that process with a level bed, then take some test cuts. I find I am only adjusting two feet exactly diagonal or opposite of each other. What's happening is I end up with only 2 feet on the floor. I don't know if that makes sense.