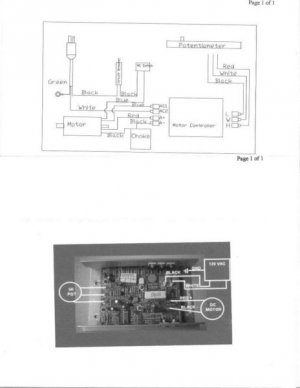

I made this Word Doc with the wiring diagram, parts list, basic prices I paid and some finished photos of the conversion on my Central Machinery wood lathe from the stock motor to a DC treadmill motor using an MC-60 controller. The control box I made includes a reversing switch, jog switch, pause/run switch, 5k POT and a digital RPM display. I know this forum is for metal working, but the doc should be helpful to anyone wanting to DC power any machine. Some of the information in the file came from this forum, and I want to thank those who provided it during my research; John Herrmann, Forty Niner & FanMan. Sorry if I let anyone out.

I found that tracking down answers to all of my questions when I first started on the project was difficult. The information was out there, but not in one place and not organized. My hope is that this doc will help someone save time when they start researching using a treadmill motor and a MC-60 controller.

The link to the file is below.

https://dl.dropboxusercontent.com/u/22075535/MC-60 Wiring Diagram with Options.docx

Quiller

I found that tracking down answers to all of my questions when I first started on the project was difficult. The information was out there, but not in one place and not organized. My hope is that this doc will help someone save time when they start researching using a treadmill motor and a MC-60 controller.

The link to the file is below.

https://dl.dropboxusercontent.com/u/22075535/MC-60 Wiring Diagram with Options.docx

Quiller