- Joined

- Nov 25, 2016

- Messages

- 175

Greetings... several hours of research has narrowed solution space on an indexing rotary capability and appear to be at the limits of my ability to contribute further. What I end up selecting at this point appears to be describable by most of the following.

A rotary table with indexing capability instead of an index table. Perhaps to include super spacer capability on top of the general indexing rather than as a replacement for it. One of my greatest (recognized) uncertainties is the value of super-spacing on top of indexing. Super spacer capability appears to more than double the cost for any given size table for a particular brand.

6 or 8" with 8 seeming to make more sense. FYI, this is going on a PM 935.

Big preference for Taiwan (of course I'd be.. willing.. to consider Switzerland or Germany and big preference for manufacturers willing to actually put their name on it.

and big preference for manufacturers willing to actually put their name on it.

Specific products that seem like good solutions to my zero-experience eyes, in two groupings:

The super-spacer group:

CW

A rotary table with indexing capability instead of an index table. Perhaps to include super spacer capability on top of the general indexing rather than as a replacement for it. One of my greatest (recognized) uncertainties is the value of super-spacing on top of indexing. Super spacer capability appears to more than double the cost for any given size table for a particular brand.

6 or 8" with 8 seeming to make more sense. FYI, this is going on a PM 935.

Big preference for Taiwan (of course I'd be.. willing.. to consider Switzerland or Germany

Specific products that seem like good solutions to my zero-experience eyes, in two groupings:

The super-spacer group:

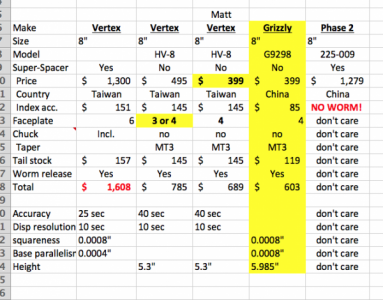

- The cost is no object solution appears to be the Vertex 8" super spacer rotary table with indexing accessories. No missing functionality. The 2000-blade Swiss Army knife..... back home in your drawer

- I like what I hear about Phase 2 but cannot determine if their 8" super spacer includes the indexing bits (sector arms, plates, etc).

- Grizzly H7506.. I think this just a 6" table but with an 8" face plate. Mitigating factor? No apparent dividing bits.. show stopper if true.

- Vertex 8" RT... dividing HW available... half the cost of the SS.

- Grizzly - multiple 8" RT... dividing HW avail

- Does it generally work out that doubling the cost of this solution to have access to SS is worth it? I know you can't speak for me... for the collective "you"... generally.

- Since all of these are RT's a their core, I assume they are all also 90:1 instead of the 40:1 of a dedicated indexing head. I realize there is probably more precision in RT mode with 90:1 but it seems like that would get old quickly with lots of index work. Anyone with personal experience on this?

- 10" non-SS RT's are obviously more precise as RT's... Any value in someone not making parts for F35's to go up to 10?

CW