-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Delta Band saw vibration

- Thread starter Janderso

- Start date

- Joined

- Mar 3, 2013

- Messages

- 1,448

On my saw which I believe is a few years older than yours it has two grooves on the "shifter rod". There are O-rings that fit in the grooves to provide some friction so the "shifter rod" doesn't move.

- Joined

- Mar 26, 2018

- Messages

- 8,407

Hmm, that sounds interesting.On my saw which I believe is a few years older than yours it has two grooves on the "shifter rod". There are O-rings that fit in the grooves to provide some friction so the "shifter rod" doesn't move.

I just ran the saw in both modes for a few minutes. The vibration is better but the lower wheel and lower bearings have to be replaced.

I guess putting tension on the blade and wheels while in storage for over ten years plays havoc on parts.

- Joined

- Jan 20, 2016

- Messages

- 173

180 degrees from the groove there is a hole in the hub. Not threaded

That is the access hole to knock the roll pins back out if ever needed.

My shifter inner shaft had 1 o ring in front of the wick in front of the threaded adjuster. I just put the old one back in, as could not find one locally. Mine stays in whatever drive adapter I put it into, despite sliding easily while shifting. Have seen other comments about it not staying in gear, so maybe I just got lucky.

What I have noticed with mine in the metal range, I occasionally get a squeal between the wood pulley and the bronze/brass sleeve. First time I just squirted some oil there, and lasted maybe 2 hours of use. Did same 2nd time, but guess I have take the end off again and grease it.

- Joined

- Mar 26, 2018

- Messages

- 8,407

I was curious about that brass bushing also.

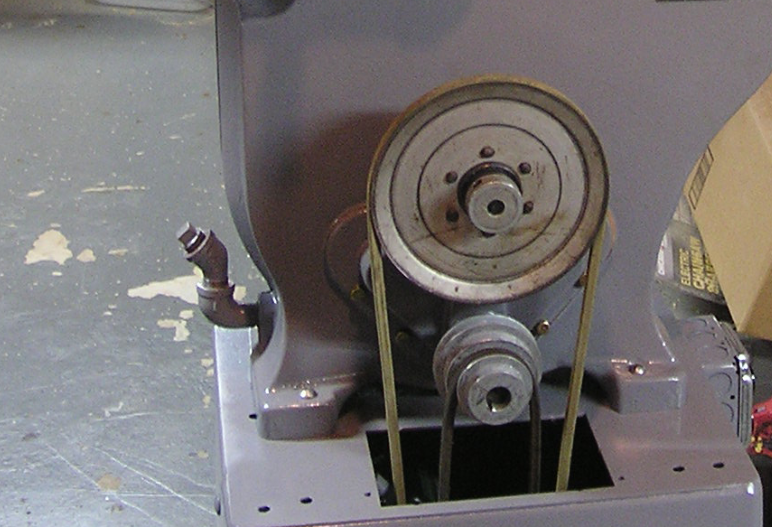

I removed the lower bent wheel. That enabled me to drive out the shaft to remove the gear box.

The pic of the worm gear has some coagulated gear oil. I don't see any shiney points on the large gear or the worm. I'm wondering if this has ever been used?

The manual said the saw is shipped with 1.5 quarts of gear oil. This cavity holds much more than that to get it up to the level of the bottom of the large gear.

There is a hole in the cover to allow for oil to be picked up by the large gear.

I think the noise I was picking up was a dry set of gears. I put a quart and a half in after I drained it. That is not enough. The cavity is huge.

I think I will fill it to the edge of the housing before I reinstall the gear box. I'm replacing the shaft bearings, they felt a little dry. A bearing that sits for 20 years without any rotation has got to have some corrosion.

I removed the lower bent wheel. That enabled me to drive out the shaft to remove the gear box.

The pic of the worm gear has some coagulated gear oil. I don't see any shiney points on the large gear or the worm. I'm wondering if this has ever been used?

The manual said the saw is shipped with 1.5 quarts of gear oil. This cavity holds much more than that to get it up to the level of the bottom of the large gear.

There is a hole in the cover to allow for oil to be picked up by the large gear.

I think the noise I was picking up was a dry set of gears. I put a quart and a half in after I drained it. That is not enough. The cavity is huge.

I think I will fill it to the edge of the housing before I reinstall the gear box. I'm replacing the shaft bearings, they felt a little dry. A bearing that sits for 20 years without any rotation has got to have some corrosion.

Attachments

- Joined

- Jan 20, 2016

- Messages

- 173

My saw supposedly sat for 3-4 years when I got it, and the motor was not running when I tried to power it up. Tore it down without running it at all. When I tore it down, my gears did have shiny / wear spots from being used, but were almost dry. It was fill to top of the fill plug when I got it, but still not much on the big top gear. I knew as soon as I had it apart that I didn't want to repeat what had been done before, wanted it lubed better.

Just a simple drain plug removal does not empty out all the oil in the lower side pockets. Unless you really tip it side to side, perhaps a 1/4 – 1/2 quart remains it those lower side pockets after a drain. Adding the 1-1/2 quarts to the residual in sump for a drain/fill, you are near the 2 full quarts I have in mine after a complete tear-down/empty re-fill. Surprised, or dismayed to hear, that your gear wasn’t wetter with that much oil.

I decided to overfill mine with slightly thinner oil to try to lube the upper gears / bearings better. I read where some tipped the saw over to left side a bit to fill more oil on right side fill port, but I decided to add extra fittings to raise my fill port up about 1-1/2 inches higher. I had this height about lined up with the bottom of the gear being submerged while the triangular gear cover was off, so hopefully it might splash around better inside than before.

I went with 75-90 w synthetic, to help it flow/splash inside easier than the thick 140ish w that was in there. I don’t envision those gears being under enough load to need anything thicker. I have 2 full quarts in mine after a complete tear-down/empty, with my higher fill ports and saw level, so am probably at about the same level you were with a drain and 1-1/2 quart re-fill? My saw is now bolted to my new roll around stand, so don't want to try tipping it over to fill it. I think I might be able to get a little bit more in there without tipping it over, so will have to re-check now that I have 4-5 hours of use on it.

Just a simple drain plug removal does not empty out all the oil in the lower side pockets. Unless you really tip it side to side, perhaps a 1/4 – 1/2 quart remains it those lower side pockets after a drain. Adding the 1-1/2 quarts to the residual in sump for a drain/fill, you are near the 2 full quarts I have in mine after a complete tear-down/empty re-fill. Surprised, or dismayed to hear, that your gear wasn’t wetter with that much oil.

I decided to overfill mine with slightly thinner oil to try to lube the upper gears / bearings better. I read where some tipped the saw over to left side a bit to fill more oil on right side fill port, but I decided to add extra fittings to raise my fill port up about 1-1/2 inches higher. I had this height about lined up with the bottom of the gear being submerged while the triangular gear cover was off, so hopefully it might splash around better inside than before.

I went with 75-90 w synthetic, to help it flow/splash inside easier than the thick 140ish w that was in there. I don’t envision those gears being under enough load to need anything thicker. I have 2 full quarts in mine after a complete tear-down/empty, with my higher fill ports and saw level, so am probably at about the same level you were with a drain and 1-1/2 quart re-fill? My saw is now bolted to my new roll around stand, so don't want to try tipping it over to fill it. I think I might be able to get a little bit more in there without tipping it over, so will have to re-check now that I have 4-5 hours of use on it.

- Joined

- Jul 29, 2014

- Messages

- 2,728

The problem I have with bandsaw vibration is how much is too much, since there is always some. When I complained about my new Laguna 1412, they had me load an accelerometer app on my iphone and tell them the numbers, ”Yep, that’s fine”, they said. It still vibrates but it got me off the line pretty effectively. i would be curious if anybody else has measured in this way, perhaps we could compare readings.

- Joined

- Mar 26, 2018

- Messages

- 8,407

Grandpop.

When I drained out the oil I put in it I tipped it way over to get most of it out. When I took the bolts out to remove the gear box I assumed it would drip some oil. The cavity was darn near empty.

There must have been some differences in these castings. I can't imagine why a manufacturer would say to put 1.5 qts just to cause damage to their product.

When I drained out the oil I put in it I tipped it way over to get most of it out. When I took the bolts out to remove the gear box I assumed it would drip some oil. The cavity was darn near empty.

There must have been some differences in these castings. I can't imagine why a manufacturer would say to put 1.5 qts just to cause damage to their product.

- Joined

- Mar 26, 2018

- Messages

- 8,407

The fill port is not the best way to fill gear oil. The air bubbles bleed slowly.

After 1 1/2 quarts I was under the impression it showed fluid at the bottom of the bend.

I’m not convinced it was full no.

But it had to be. I put in one and a half qts.!

After 1 1/2 quarts I was under the impression it showed fluid at the bottom of the bend.

I’m not convinced it was full no.

But it had to be. I put in one and a half qts.!