- Joined

- Dec 18, 2019

- Messages

- 6,593

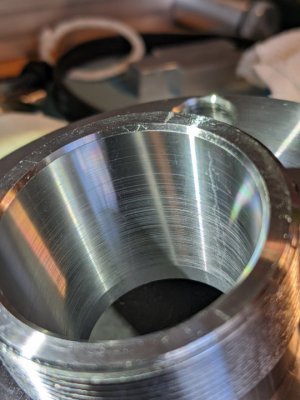

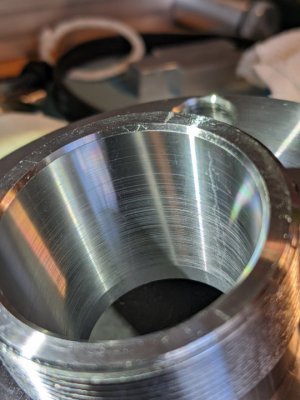

So I'm finishing up a set tru back plate for a Shars ER40 set tru chuck. All that is left to do is to true the TIR (using the ER taper) and to slightly turn the OD of the back plate to get it slightly closer to that of the chuck. Don't have any ER40 collets yet, so that's as far as I can get for now. Lightly installed the chuck on the back plate. Bolts not tightened but partially snugged. For the first time (that I remember) I unscrew the collet nut. This is so I can get a DTI in to measure the TIR. Look in the ER taper and see that it's scored.  Rub the back of my fingernail down the taper, yes, it catches a lot. It is rough. Well, I feel kind of dumb. Why didn't I notice this before? Did I assume that since it was new, it would be ok? Kind of flabbergasted and a bit low at the moment. Should be a smooth ground surface, right? My ER32 chuck taper is ground.

Rub the back of my fingernail down the taper, yes, it catches a lot. It is rough. Well, I feel kind of dumb. Why didn't I notice this before? Did I assume that since it was new, it would be ok? Kind of flabbergasted and a bit low at the moment. Should be a smooth ground surface, right? My ER32 chuck taper is ground.

My original photo shows scoring. I do not know how bad this forum will blur the picture.

I will call Shars today. This isn't an email kind of conversation. The scoring seems to increase the deeper into the taper one goes. Can't tell if this was a return or not, everything else looks rather pristine. It's like a collet spun in it. I don't know that, of course, but what could cause something like this?

My original photo shows scoring. I do not know how bad this forum will blur the picture.

I will call Shars today. This isn't an email kind of conversation. The scoring seems to increase the deeper into the taper one goes. Can't tell if this was a return or not, everything else looks rather pristine. It's like a collet spun in it. I don't know that, of course, but what could cause something like this?