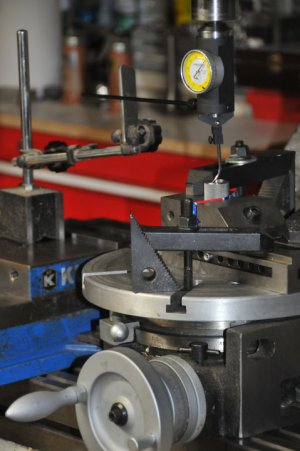

I made this so I could use my 5/8" hex dies on the arbor I had bought for round dies. After drilling and reaming for the arbor I drilled for the die and then set it up on the rotary table in a tool makers vice. Aluminum pop can was used to protect the knurls. I used a HSS 1/8" end mill, DOC .025 (after some experimenting to see what worked.) 3000 rpm. After all the straight cuts were done, I used the end mill to "drill" out the round corners. Got good fits and gave it a try on the lathe. 1/4-28 on aluminum. Got a very clean thread. I still need to make a cross bar handle for it if I'm going to use it on steel. I've got two more to make in different sizes.

-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

Die threading on lathe

- Thread starter Larry$

- Start date