- Joined

- Aug 5, 2018

- Messages

- 261

Hi,

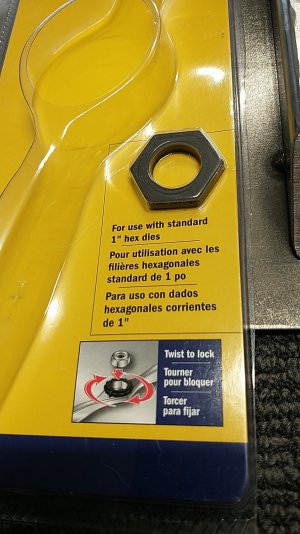

I was recently told that there are differences between hexagon shaped dies and round dies; hex dies are for repairing threads while round dies are for cutting new.

This doesn't make sense to me. I would think that the shape of the hex die would make cutting easier due to the fact that the die shape would prevent it turning in the die holder where as the round might turn with the work.

Also, I was told, that the hex dies are slightly tighter than the round because of their designed purpose - to fix bad threads.

Now from watching some youtube videos regarding machining small parts for kits, the machinist always uses round dies when cutting threads and, some have an adjustment screw that I guess, acts like a wedge to open the die a few thousands. Can't imagine more than that simply because there's no hinge on the opposite side.

Can someone clarify all this for me please. The internet was less than helpful.

Red.

I was recently told that there are differences between hexagon shaped dies and round dies; hex dies are for repairing threads while round dies are for cutting new.

This doesn't make sense to me. I would think that the shape of the hex die would make cutting easier due to the fact that the die shape would prevent it turning in the die holder where as the round might turn with the work.

Also, I was told, that the hex dies are slightly tighter than the round because of their designed purpose - to fix bad threads.

Now from watching some youtube videos regarding machining small parts for kits, the machinist always uses round dies when cutting threads and, some have an adjustment screw that I guess, acts like a wedge to open the die a few thousands. Can't imagine more than that simply because there's no hinge on the opposite side.

Can someone clarify all this for me please. The internet was less than helpful.

Red.