- Joined

- Dec 25, 2017

- Messages

- 141

This was a couple of years ago, but I thought you guys would enjoy seeing it.

I have a tandem bike in my stable ( three actually ). I use it for decently fast club rides and keeping weight and rolling resistance down matter as we climb the rockies around here with kid’s half my age.

The bike got caught up in a recall by Canondale to replace the original aluminum fork. A few had broken, with injuries. By the time I got wind of this they had run out of replacement forks but did agree to install a new carbon/aluminum fork. I got carried away with this unplanned upgrade and put on new, lighter, tubeless, wheels. Over all the bike came out 4 pounds lighter. Neat.

What you machinists care about is that the front brake disc did not fit onto the Shimano adapter needed for the hubs of the new wheels. The old wheels were 6-bolt and the new are CenterLock, splined.

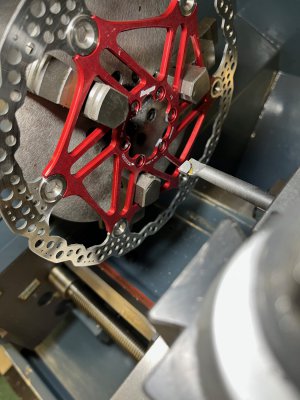

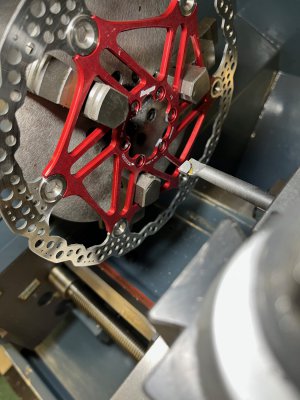

Shaving a millimeter off the ID of the brake disc would allow a fit. But taking off too much threatened weakening the disc mounting. After some head scratching I decided to take the bold route and turn the disc on my 13x40 lathe. This is easily the most fragile item I have turned. Every bit of it has minimum mass. A thin stainless steel ring where the brake pads ride and a spidery anodized aluminum inner framework.

I managed to carefully mount it in the 3-jaw, pretty well centered. Spun it slow and shaved off that millimeter.

Here are photos.

I have a tandem bike in my stable ( three actually ). I use it for decently fast club rides and keeping weight and rolling resistance down matter as we climb the rockies around here with kid’s half my age.

The bike got caught up in a recall by Canondale to replace the original aluminum fork. A few had broken, with injuries. By the time I got wind of this they had run out of replacement forks but did agree to install a new carbon/aluminum fork. I got carried away with this unplanned upgrade and put on new, lighter, tubeless, wheels. Over all the bike came out 4 pounds lighter. Neat.

What you machinists care about is that the front brake disc did not fit onto the Shimano adapter needed for the hubs of the new wheels. The old wheels were 6-bolt and the new are CenterLock, splined.

Shaving a millimeter off the ID of the brake disc would allow a fit. But taking off too much threatened weakening the disc mounting. After some head scratching I decided to take the bold route and turn the disc on my 13x40 lathe. This is easily the most fragile item I have turned. Every bit of it has minimum mass. A thin stainless steel ring where the brake pads ride and a spidery anodized aluminum inner framework.

I managed to carefully mount it in the 3-jaw, pretty well centered. Spun it slow and shaved off that millimeter.

Here are photos.

Last edited: