-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

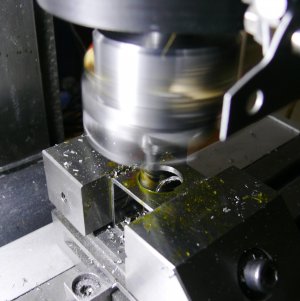

DIY Boring Head

- Thread starter werz99

- Start date

-

- Tags

- boring head

- Joined

- Dec 6, 2015

- Messages

- 810

That looks great!

Sent from my SM-T500 using Tapatalk

Sent from my SM-T500 using Tapatalk

- Joined

- Dec 21, 2013

- Messages

- 798

Nice job ! I made a 2" boring head fer myself a year or three ago, it sure feels good to use

a tool that you made fer yourself. I posted mine in the shop made tool forum also ..............

a tool that you made fer yourself. I posted mine in the shop made tool forum also ..............

Very cool! Is this the Steve Campbell design boring head? If so I made the same one about a year or so ago except I used a 60 degree dovetail and made a few minor changes to meet my needs. I needed a small accurate boring head and the Chinese ones just wouldn't cut it so I made my own. It works very very well and is solid. I plan on building another one (2" diameter) and I am going to make a few changes so that I can use an indexable attachment like Mesa Tools makes for the Criterion heads.

Here's a link to mine. https://www.hobby-machinist.com/thr...cutter-for-making-homemade-boring-head.71700/

And here's the Mesa tool attachment https://www.mesatool.com/product-page/2-boring-head-attachment

Here's a link to mine. https://www.hobby-machinist.com/thr...cutter-for-making-homemade-boring-head.71700/

And here's the Mesa tool attachment https://www.mesatool.com/product-page/2-boring-head-attachment

Nice machined boringhead you made!

Thanks for the tipps with the mesa-attachment. - Very interesting addon that is now on my todo-list and needs further research..

I also have a 60° dovetail (copying the design of randy richards for the cutter) and I never heard of the "Steve Campbell Design" - just looked at several solutions and made my own version for my small mill. Also planning an even smaller version...

Thanks for the tipps with the mesa-attachment. - Very interesting addon that is now on my todo-list and needs further research..

I also have a 60° dovetail (copying the design of randy richards for the cutter) and I never heard of the "Steve Campbell Design" - just looked at several solutions and made my own version for my small mill. Also planning an even smaller version...

Thanks. The 60° dovetail was my initial concern but it made no difference at all. The only reason I see now to use a 45 over a 60 is if the boring head is even smaller and your looking for more contact area of the dovetail.Nice machined boringhead you made!

Thanks for the tipps with the mesa-attachment. - Very interesting addon that is now on my todo-list and needs further research..

I also have a 60° dovetail (copying the design of randy richards for the cutter) and I never heard of the "Steve Campbell Design" - just looked at several solutions and made my own version for my small mill. Also planning an even smaller version...

View attachment 368750

Here is a link to another pic of the Mesa attachment that shows you more of its construction.

www.mesatool.com

www.mesatool.com

3″ Boring Head Attachment – Adjustable w/TPGB-321 | mesatool

Heavy duty! Take heavier cuts…Interrupted cuts no problem! Bore range increases by reversing tool in the head. Comes with one TPGB-321 insert. Will accept any similar inserts. Comes with one standard 4-40 Torx screw. Fits 3″ boring heads with odd hole offset.Adjustable drive pin accommodates...