- Joined

- Oct 15, 2020

- Messages

- 208

It seems a bit redundant to say "DIY" regarding anything on this site doesn't it....

SO!

My sweetie responded, as sweeties do, to my complaints regarding my beard-cutter machine. You see, I had been using some old 110VAC clipper thing that I found somewhere, years ago. It was missing teeth and was dull, and so pulled the beard rather than cut the beard... the joys of long-term bachelordom

... Incidentally, a real man shaves with a sharp rock, using cactus for lather, and can strike a match on his chin, so there is that

Anywho, I got a new beard gizmo, and so was left with something that worked fine, but had no use... If you're a hobby machinist, you know what a moral dilemma it is to consider throwing away something that works!

With fond boyhood memories of me gran'pappy teaching me about inductive coupling, using a similarly discarded hair-clipper-thing, I recalled that within these AC powered devices there is the simplest of oscillating motors: some bell wire around a laminated iron core. Granddad turned that old one into a neat step-down transformer.

I recalled, when working at the Tool and Die Shop, having disassembled the de-mag once to fix its switch. The function of the thing is immediately apparent: AC goes up and down to make a 60Hz oscillating magnetic field, this outlaws the freedom of assembly among the ferro-dudes within the steel, thusly demagnetizing the part (yes, it is a bit more complicated than that, but that's pretty much what it does).

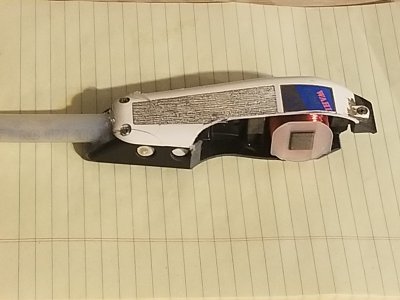

I disassembled my former beard-cutting machine, removed the alarming amount of historic beard-hair that had secreted itself within (had it for many bristly days), cut the casing to expose the business-end of the electromagnet, then added a bit of stiff nylon tubing to act as a handle.

While modifying the case, it broke but! As I intended to employ the omnipotent hot-glue-extruder, I carried on!

but! As I intended to employ the omnipotent hot-glue-extruder, I carried on!

I cut out a chunk of Not-Leather (I think it was a bull**** purse or something from which I had made a book-cover for a friend) and applied it to the gaping hole as a makeshift "Flux emission window" (You see what I did there? Made it all officially scientific with snooty terminology!)

I then wrapped a lowe's shopping bag about the handle end to make it thicker, and covered the thing in the ugliest electrical-tape that I could find.

TADA!!!

An Oscillating Flux Ferro-Randomizing Wand!!!

If you'll notice, as it is chincy as chincy can be, I must make use of more and more snooty terminology....

Anyways, put it near aluminum and the aluminum gets all angry - on account of Lenz and whatnot.

Put it near a drill-bit, and the fuzz will fall away of its own accord....

(Come to think of it, it is still a beard-trimmer, in that it removes the iron beards from pieces-parts-and-tools! HAHAHAHAA!!!)

I demagged some screw-drivers, and it works exactly as anticipated.

Then Sweetie told me that some people want their screwdrivers to be magnetic, so I guess I've got to contrive a DC equivalent now to de-demag what was previously magged, but then was de-magged....

Anywho, two pictures show the thing - ugly and really simple.

In seriousness though, every de-mag I've seen has been a benchtop model - building one as a wand seems more intuitive.

.... I wonder what would happen if I put it near my metal detector wand?

Thank you for looking!

SO!

My sweetie responded, as sweeties do, to my complaints regarding my beard-cutter machine. You see, I had been using some old 110VAC clipper thing that I found somewhere, years ago. It was missing teeth and was dull, and so pulled the beard rather than cut the beard... the joys of long-term bachelordom

... Incidentally, a real man shaves with a sharp rock, using cactus for lather, and can strike a match on his chin, so there is that

Anywho, I got a new beard gizmo, and so was left with something that worked fine, but had no use... If you're a hobby machinist, you know what a moral dilemma it is to consider throwing away something that works!

With fond boyhood memories of me gran'pappy teaching me about inductive coupling, using a similarly discarded hair-clipper-thing, I recalled that within these AC powered devices there is the simplest of oscillating motors: some bell wire around a laminated iron core. Granddad turned that old one into a neat step-down transformer.

I recalled, when working at the Tool and Die Shop, having disassembled the de-mag once to fix its switch. The function of the thing is immediately apparent: AC goes up and down to make a 60Hz oscillating magnetic field, this outlaws the freedom of assembly among the ferro-dudes within the steel, thusly demagnetizing the part (yes, it is a bit more complicated than that, but that's pretty much what it does).

I disassembled my former beard-cutting machine, removed the alarming amount of historic beard-hair that had secreted itself within (had it for many bristly days), cut the casing to expose the business-end of the electromagnet, then added a bit of stiff nylon tubing to act as a handle.

While modifying the case, it broke

but! As I intended to employ the omnipotent hot-glue-extruder, I carried on!

but! As I intended to employ the omnipotent hot-glue-extruder, I carried on!I cut out a chunk of Not-Leather (I think it was a bull**** purse or something from which I had made a book-cover for a friend) and applied it to the gaping hole as a makeshift "Flux emission window" (You see what I did there? Made it all officially scientific with snooty terminology!)

I then wrapped a lowe's shopping bag about the handle end to make it thicker, and covered the thing in the ugliest electrical-tape that I could find.

TADA!!!

An Oscillating Flux Ferro-Randomizing Wand!!!

If you'll notice, as it is chincy as chincy can be, I must make use of more and more snooty terminology....

Anyways, put it near aluminum and the aluminum gets all angry - on account of Lenz and whatnot.

Put it near a drill-bit, and the fuzz will fall away of its own accord....

(Come to think of it, it is still a beard-trimmer, in that it removes the iron beards from pieces-parts-and-tools! HAHAHAHAA!!!)

I demagged some screw-drivers, and it works exactly as anticipated.

Then Sweetie told me that some people want their screwdrivers to be magnetic, so I guess I've got to contrive a DC equivalent now to de-demag what was previously magged, but then was de-magged....

Anywho, two pictures show the thing - ugly and really simple.

In seriousness though, every de-mag I've seen has been a benchtop model - building one as a wand seems more intuitive.

.... I wonder what would happen if I put it near my metal detector wand?

Thank you for looking!