- Joined

- Mar 9, 2018

- Messages

- 465

I'm pretty new to the hobby machinist game, so forgive my ignorance if I'm asking a stupid question.

I've got an old Montgomery Wards / Logan 10 x 24" lathe.

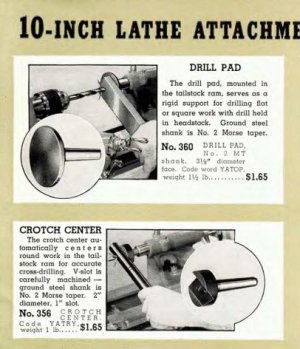

I don't have a mill or even a drill press (barely have room for the lathe, so certainly no room for anything else). I compensate for the lack of drill press by using a shop-made 'drill platen' that screws onto an MT2 arbor and nestles into the tailstock quill. I can clamp weirdly-shaped or off-center parts to the platen and use a drill chuck in the lathe spindle to drill holes. Drilling forces stay concentric with the tailstock spindle, so everything is super solid. (Has anyone ever seen that done? Seems people must have similar setups, but a few lazy google searches came up empty.)

Milling attachments for this lathe pop up on eBay every once in a while, but they're often beat to hell and always several hundred dollars. And even so, I've read many a complaint about how milling attachments for lathes are just barely better than worthless because of how flexible the setup inevitably is, what with them mounting atop the cross slide or compound rest.

So that got me thinking.... has anyone ever mounted an x/y slide table (or even a rotary table) to their tailstock and for use as a milling attachment? It must be a stiffer setup than the traditional carriage-mounted attachment. And even if not used to mill slots, it could be very useful in drilling accurately spaced holes.

The weak point, I suppose, would be how it connects to the MT2/tailstock spindle. But again, everything stays concentric with the tailstock spindle so it shouldn't be too bad.

Thanks,

JR

I've got an old Montgomery Wards / Logan 10 x 24" lathe.

I don't have a mill or even a drill press (barely have room for the lathe, so certainly no room for anything else). I compensate for the lack of drill press by using a shop-made 'drill platen' that screws onto an MT2 arbor and nestles into the tailstock quill. I can clamp weirdly-shaped or off-center parts to the platen and use a drill chuck in the lathe spindle to drill holes. Drilling forces stay concentric with the tailstock spindle, so everything is super solid. (Has anyone ever seen that done? Seems people must have similar setups, but a few lazy google searches came up empty.)

Milling attachments for this lathe pop up on eBay every once in a while, but they're often beat to hell and always several hundred dollars. And even so, I've read many a complaint about how milling attachments for lathes are just barely better than worthless because of how flexible the setup inevitably is, what with them mounting atop the cross slide or compound rest.

So that got me thinking.... has anyone ever mounted an x/y slide table (or even a rotary table) to their tailstock and for use as a milling attachment? It must be a stiffer setup than the traditional carriage-mounted attachment. And even if not used to mill slots, it could be very useful in drilling accurately spaced holes.

The weak point, I suppose, would be how it connects to the MT2/tailstock spindle. But again, everything stays concentric with the tailstock spindle so it shouldn't be too bad.

Thanks,

JR