I just got a bandsaw for free from a woodworker (my Dad). The blade in there now is presumably for cutting wood.

I don’t know much about bandsaws. Should I replace the blade with one made for cutting metal? I never work on wood.

95+% of my work is on mild steel.

This new-to-me bandsaw will be tasked to cut a lot of 45-70 kpsi tensile strength (carbon steel) weld beads.

Like most DIY bandsaws, you can use the basic thing considered as a base set of project parts, and set about making some improvements.

YouTube has lots of videos showing everything from little add-ons to complete DIY constructions. Quinn Dunki (Blondihacks) showed a project where she rigged up a hand-held bandsaw on a wall mount with a trick tilting table.

The first answer is yes - you do need to use a blade suited to the job. My choice is bi-metal M42. For cutting wood, choose 6TPI for ripping thick chunks. 6-10 variable, or 8TPI, or 10TPI for fine wood cuts on thinner stuff. For metal, 10-14TPI variable for thick chunks, and in aluminium. 14TPI for thick cast iron. Thinner metals need finer tooth pitches. You need more than a couple of teeth on the thickness of what you cut.

When you get to what's OK for steels, put stainless in a special category. The speed, technique, and lube are all very important. Generally as the steels get thin, like 3mm, or 2mm, the teeth count needs to go up. Look to 18TPI or 24TPI. With stainless, it can trash a good blade in seconds if you do it wrong. You need the lube paste, oil, or oily coolant flow. You go blade speed real slow - and go in hard! Get the blade going without rubbing, and don't stop until you are through. If you release pressure on the cut, come back away a fraction real quick. Don't let it rub.

Counter-intuitively, extremely fine toothed blades don't help much here. If the pressure is distributed on too many teeth, they can lack the point force to start cutting. Mine worked on 14TPI into 10mm stainless.

Cheap Speed Controllers

I bought a Axminster band saw claimed to be OK for woodwork and metalwork because of the variable speed power drive, so I didn't need a drive, but I did also get a variable speed drive for my drill press, which would also work on a bandsaw. About $100 should get you the right thing. Avoid those simplistic $40 little boxes that leave you with no torque.

Check advertisements very carefully, checking for

single-phase input AND

single phase output capability. There are tons that do single-phase in, and three phase out. Use 240V if you can contrive it in your shop. The one I got was "universal", able to be configured for all kinds. I show the first link as the one I purchased.

The one I bought

https://www.ebay.co.uk/itm/203098314559?

USA supply

I have not checked the specifications in detail, but here are links to USA eBay examples that might do the job.

https://www.ebay.com/itm/144662252352?

https://www.ebay.com/itm/394295165098?

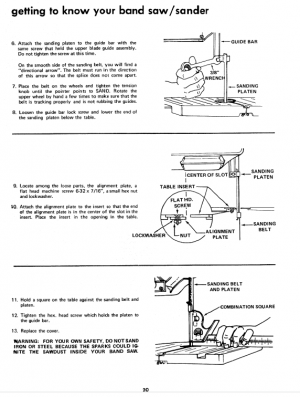

Given you got the base device for free, you might consider you have room for some upgrades. Adding on a little adjustable blade guide with four 1/2" diameter sealed ball bearings is one I have seen a video on. I see this item as a safety need, as well as something to prevent cut wandering about.

Some folk add a mist, or coolant flow pipe, though you have to pay attention to guiding and collecting wet stuff from under the table. It may be a DIY woodwork bandsaw is best kept doing what it was designed for. Having a slow-speed metal cutting ability is a huge treat, but you may want to use a more dedicated machine. That said, one can definitely turn a base bandsaw structure into a great metal cutter.

www.hobby-machinist.com

www.hobby-machinist.com

www.hobby-machinist.com

www.hobby-machinist.com