Alright... I had some time to take the motor out of the lathe, which was a giant PITA. I ended up discovering that a panel came off the lathe REALLy late, so I ended up trying to wrestle it through a hole that was only slightly too small. I FINALLY got it out though, and started tearing it apart:

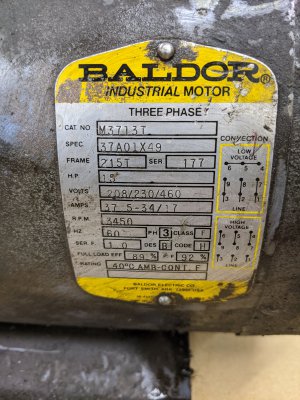

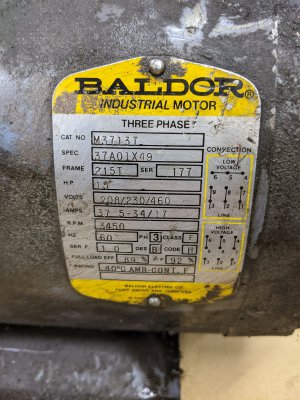

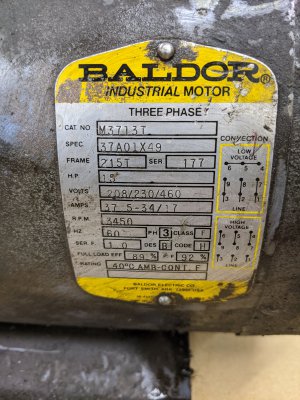

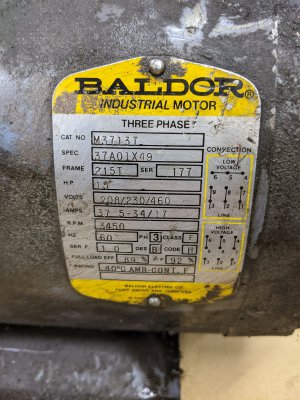

First, I gave it a wipe down, and took this picture (and of the data plate):

I used a pulley puller to take off the toothed pulley, and took off the rear fan guard. The pulley side ended up coming off pretty easy:

The rear fan I ended up breaking unfortunately (it was tac welded to a collar that was held in by a hidden-in-dirt set screw) using my pulley puller. Hopefully I can just flatten it out and JB weld it back together (or would there be a source of replacements?).

THEN, the other endcap came off. Bearings on each side are the greasy on 1 side, sealed on the other kind, and had some 'grit' to them. The pulley side (the one with an accessdoor!) had been greased it seems, but the other had a much older grease in it:

I was able to pull the back bearing off pretty easily, so the whole shaft assembly came out. It seems REALLY clean inside:

I was able to pull both bearings out reasonably easily. I ended up having to grind my pulley puller a little to get in to the pulley side, but it worked.

There was only a SINGLE wave washer on 1 side, I suspect the other should be in there too? There was a decent amount of play (I think my 1/2" was way more than it really was... I was able to move it by hand ~1/16" of an inch).

Bearing #s seem to be (fan side): 6206 C3, and pulley side: 6307 (also seemingly C3).

First, where is the easiest place to get replacements that I could also get wave washers too? Could I possibly replace these with fully sealed bearings so I don't have to worry about the grit? Does anyone know if that rear fan is replacable, or if I should just try to JB weld it back together after bending it flat again?

Thanks!