- Joined

- Jan 5, 2014

- Messages

- 944

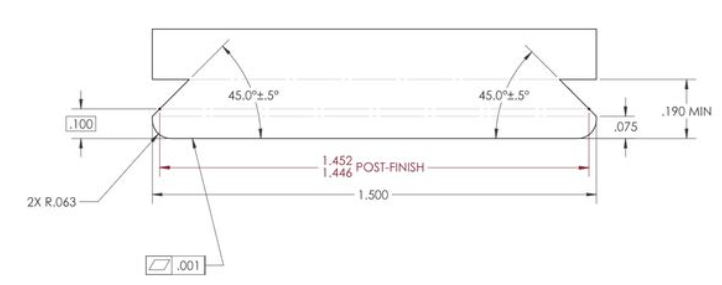

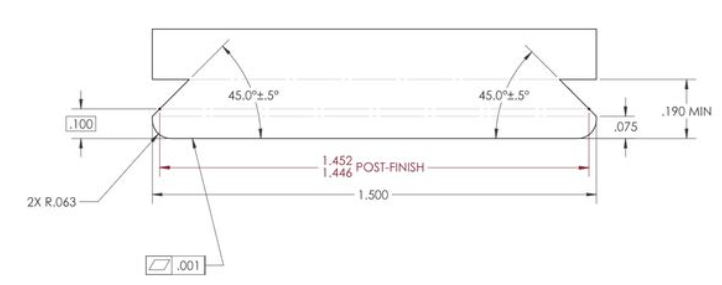

So I have a small project. I need to mill into an existing assembly an arca-swiss dovetail. Arca-swiss is a sort-of standard for mounting photography equipment to tripods, etc. The dovetail is 45 degrees and the thing I'm machining is some sort of anodized aluminum. I don't want to buy an attachable plate because I need to minimize the overall height and it happens that the rail is just slightly wider than needed, perfect.

So, I'm looking for a decent 45 Deg. dovetail cutter and a 1/16" radius cutter that will work well with aluminum. I have an RF-45 style mill, 3600 RPM maximum. What is a decent quality brand of cutter and source that won't break the bank?

Also, what is a tough, black finish I can put back on the machined surfaces? (Not anodize.)

Thanks!

Here is (roughly) the profile I'm going for.

What I'm making:

I am making a stepper-controlled focusing rail for macro photography. I found some low cost, used THK rail assemblies and I'm using one of them for this.

The rail:

![20230626_120651[1].jpg 20230626_120651[1].jpg](https://www.hobby-machinist.com/data/attachments/409/409288-d105602b689a32d1e91b23d8164a43e5.jpg)

So, I'm looking for a decent 45 Deg. dovetail cutter and a 1/16" radius cutter that will work well with aluminum. I have an RF-45 style mill, 3600 RPM maximum. What is a decent quality brand of cutter and source that won't break the bank?

Also, what is a tough, black finish I can put back on the machined surfaces? (Not anodize.)

Thanks!

Here is (roughly) the profile I'm going for.

What I'm making:

I am making a stepper-controlled focusing rail for macro photography. I found some low cost, used THK rail assemblies and I'm using one of them for this.

The rail:

![20230626_120651[1].jpg 20230626_120651[1].jpg](https://www.hobby-machinist.com/data/attachments/409/409288-d105602b689a32d1e91b23d8164a43e5.jpg)