- Joined

- Feb 21, 2022

- Messages

- 790

Excellent link, thankyou.

It proves my simple theory of using a rod diameter of 1/3rd of the dovetail depth & also shows how hard it can be.

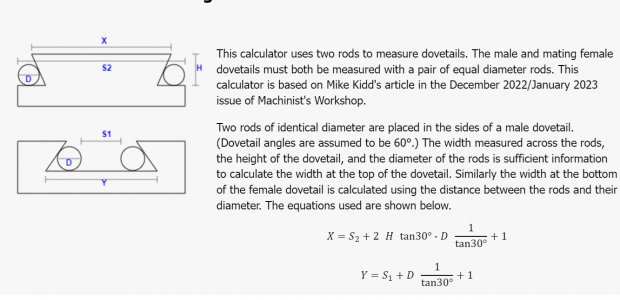

For the female - I entered S1 as 10 and a rod diameter of 3 which gave a theoretical sharp corner distance of 18.196.

For the male - I entered S2 as 16 ( S1 + 2 rollers ) rod diameter again as 3 with a height H of 9 ( 3x rod dia ). and gave the same distance of 18.196.

Proving that only a rod diameter of 1/3 the depth gives the same dimension over the correct size rollers for both parts.

It also shows this formulae if you prefer...