- Joined

- Mar 20, 2024

- Messages

- 64

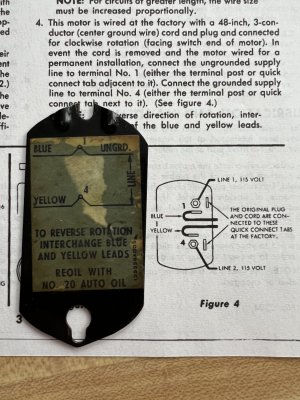

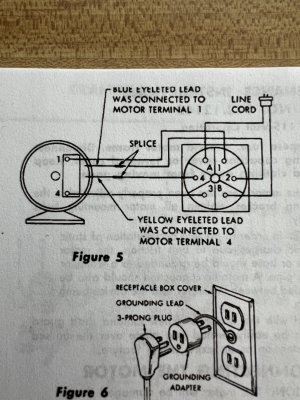

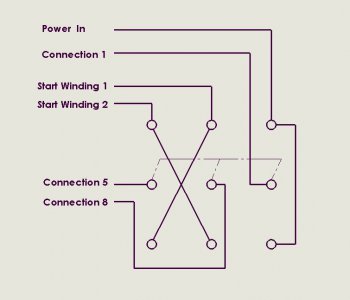

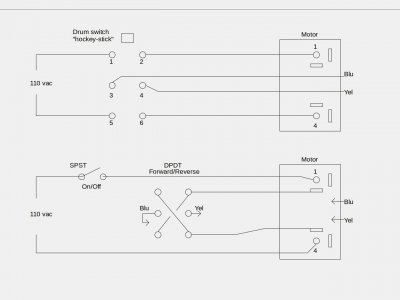

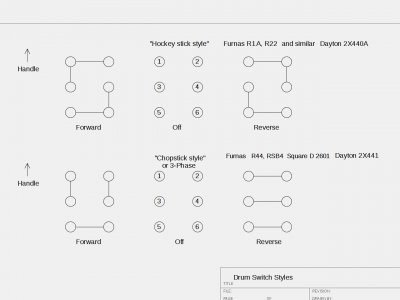

I have a Gen 2 Craftsman 150 drill press I’m working on getting in order. It has a 113.12140 motor on it with reverse capability via swapping wires on the control panel. I don’t know why but I’m having a massive brain fog as to how I could wire this to a dpdt toggle. I have a on/off/on switch that I’d like to use and I think as long as I let the motor come to a complete stop I’d be good to go with it. If I could figure out the wiring! Idk why but the yellow and blue wires are blocking me from processing it. Any input? Here are some pictures. The switch is just a simple toggle. Any help here would be much appreciated!